- The GT-7046-HS1 is well-suited for materials with low permeability and waterproof treatment such as plastics, waterproof canvases, and fabrics.

- This instrument is specifically designed to determine the ability of various materials to resist water penetration.

-

Standards

- GB/T 4744-2013

- ISO 811:2018

- AATCC 127-2017

- QB/T 4744

PRINCIPLE

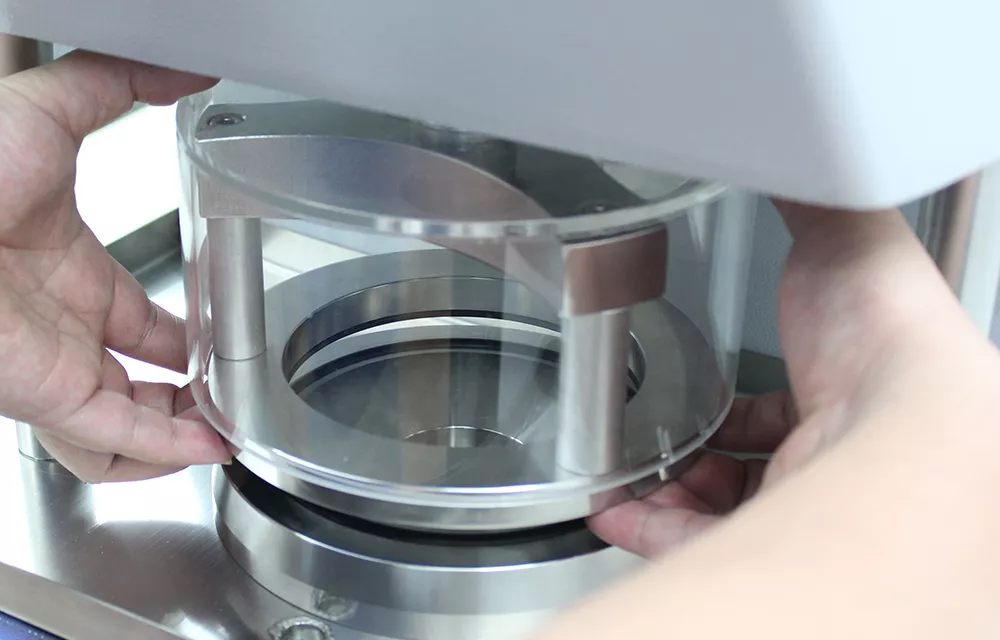

The GT-7046-HS1 is specifically designed to determine the water penetration resistance of materials. It features a servo-controlled motor as the driving source and adjustable water pressure from 2 to 20000mmH2O. During the test, the tester applies pressure steadily to the test specimen at a specified ramp rate or maintains the applied pressure for a specified period of time to assess the materials' resistance to water penetration.

Wide material applications:

Well-suited for assessing the water penetration resistance of materials with high density, low permeability, and waterproof treatment such as plastics, waterproof canvases, and fabrics across different industries.

Material research and development:

Supports manufacturers in evaluating new materials' water penetration resistance under high water pressure during research and development.

Waterproof material evaluation:

Suitable for evaluating materials with waterproof treatment such as waterproof fabrics and membranes.

Quality assurance:

Assists manufacturers in ensuring and maintaining product quality to meet specific testing requirements.

Textile waterproofness testing:

Provides valuable insights into the water penetration resistance of textile and fabrics, ensuring their protection performance in humid environments.

Waterproof apparel testing:

Verify that waterproof outwear or apparel can withstand penetration under various water pressures, meeting the requirements for outdoor activities.

Scientific research:

Guides researchers in advancing material science by studying the behavior of water penetration resistance among different materials.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Precision control system

Utilizes an advanced servo-controlled motor as the driving source to achieve precision control during tests, ensuring testing accuracy.

Stable pressure ramp rate

Provides a stable pressure ramp rate to apply pressure to the test specimen, ensuring consistency, stability, and repeatability throughout the testing process.

Adjustable pressure

Offers a broad range of adjustable water pressure from 2 to 20000mmH2O, meeting diverse testing requirements for various material applications.

Data storage and analysis

With a database and analysis system, this instrument can record data and analyze test results upon completion of tests.

Touchscreen interface

The touchscreen interface offers an intuitive and user-friendly experience, allowing operators to effortlessly set up parameters and operate the tester.

Efficiency

Featuring automatic operation, this instrument offers efficient testing, reducing the need for intervention during production processes.

-

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Pressure sensor Pressure cell Pressure range 1 to 2000cm H2O 1 to 5000cm H2O Pressure detection (1 to 2000)cm H2O or, (1 to 5000)cm H2O or, (0.098 to 196)kPa or, (0.098 to 490)kPa or, (0.001 to 2)kg/c㎡ (0.001 to 5)kg/c㎡ Force accuracy ≤ ±0.5% Pressure increasing rate (10 to 2000) cm H2O /min or, (1.00 to 196) kPa/min or, (0.01 to 2) kg/c㎡/min Speed accuracy ≤ ±0.5% Test area 100c㎡ and 20c㎡ Controller U70 control system Motor AC servo motor Compressed air 5 kg/c㎡ (air compressor required) Dimension (W×D×H) 40×53×60 cm Weight (approx.) 90 kg Power 1∮, AC 220V, 2A (or specify)

-

-

Details

Standards

- GB/T 4744-2013

- ISO 811:2018

- AATCC 127-2017

- QB/T 4744

PRINCIPLE

The GT-7046-HS1 is specifically designed to determine the water penetration resistance of materials. It features a servo-controlled motor as the driving source and adjustable water pressure from 2 to 20000mmH2O. During the test, the tester applies pressure steadily to the test specimen at a specified ramp rate or maintains the applied pressure for a specified period of time to assess the materials' resistance to water penetration.

Wide material applications:

Well-suited for assessing the water penetration resistance of materials with high density, low permeability, and waterproof treatment such as plastics, waterproof canvases, and fabrics across different industries.

Material research and development:

Supports manufacturers in evaluating new materials' water penetration resistance under high water pressure during research and development.

Waterproof material evaluation:

Suitable for evaluating materials with waterproof treatment such as waterproof fabrics and membranes.

Quality assurance:

Assists manufacturers in ensuring and maintaining product quality to meet specific testing requirements.

Textile waterproofness testing:

Provides valuable insights into the water penetration resistance of textile and fabrics, ensuring their protection performance in humid environments.

Waterproof apparel testing:

Verify that waterproof outwear or apparel can withstand penetration under various water pressures, meeting the requirements for outdoor activities.

Scientific research:

Guides researchers in advancing material science by studying the behavior of water penetration resistance among different materials.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Precision control system

Utilizes an advanced servo-controlled motor as the driving source to achieve precision control during tests, ensuring testing accuracy.

Stable pressure ramp rate

Provides a stable pressure ramp rate to apply pressure to the test specimen, ensuring consistency, stability, and repeatability throughout the testing process.

Adjustable pressure

Offers a broad range of adjustable water pressure from 2 to 20000mmH2O, meeting diverse testing requirements for various material applications.

Data storage and analysis

With a database and analysis system, this instrument can record data and analyze test results upon completion of tests.

Touchscreen interface

The touchscreen interface offers an intuitive and user-friendly experience, allowing operators to effortlessly set up parameters and operate the tester.

Efficiency

Featuring automatic operation, this instrument offers efficient testing, reducing the need for intervention during production processes.

-

Specifications

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Pressure sensor Pressure cell Pressure range 1 to 2000cm H2O 1 to 5000cm H2O Pressure detection (1 to 2000)cm H2O or, (1 to 5000)cm H2O or, (0.098 to 196)kPa or, (0.098 to 490)kPa or, (0.001 to 2)kg/c㎡ (0.001 to 5)kg/c㎡ Force accuracy ≤ ±0.5% Pressure increasing rate (10 to 2000) cm H2O /min or, (1.00 to 196) kPa/min or, (0.01 to 2) kg/c㎡/min Speed accuracy ≤ ±0.5% Test area 100c㎡ and 20c㎡ Controller U70 control system Motor AC servo motor Compressed air 5 kg/c㎡ (air compressor required) Dimension (W×D×H) 40×53×60 cm Weight (approx.) 90 kg Power 1∮, AC 220V, 2A (or specify)

-

Video