- The GT-7042-RE is specifically designed to assess the rebound resilience of elastomers.

- This instrument applies the pendulum method, utilizing a hammer of specific mass to strike samples for assessing rebound resilience.

-

Standards

- DIN 53512

PRINCIPLE

The GT-7042-RE is specifically designed to assess the rebound resilience of elastomers. This instrument applies the pendulum method, utilizing a hammer of specific mass to strike samples for assessing rebound resilience.

Wide applicability:

Well-suited for a wide range of industries such as rubber, plastics, material science, footwear, automotive, electronics, construction, medical devices, and industrial manufacturing.

Material performance assessment:

Helps manufacturers to evaluate the resilience of elastomers to impact under different scenarios to optimize material selection.

Product design improvement:

Enables designers to observe how different materials respond to impact, allowing for adjustments to be made before mass production to improve durability and safety.

Standardized test procedure:

Utilizes a standardized test procedure to provide objective test results and repeatable assessments, ensuring conformity to rebound resilience standards.

Quality assurance:

Ensuring that products consistently meet specific standards for quality, reducing defect rate in production and manufacturing.

High efficiency:

Providing simplified and efficient operation procedures to reduce both operation time and effort.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Rebound results indicator

Precisely measures and indicates the test result on a rebound scale for rebound resilience assessment.

Hand-operated clamp

Utilizes manual clamping device to secure sample on the anvil, ensuring stability during testing processes.

Easy operation

Featuring easy setup and test procedures, the GT-7042-RE enables operators to conduct rebound resilience tests effortlessly.

-

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Impact energy 0.5J Indicator scale range 0 to 100 % Minimum graduation on indicator scale 1% Length of pendulum 200±0.5 mm Drop angle 90° Impact speed 2 m/sec Range of specimen thickness 0 to 60 mm Minimum graduation on movable shaft scale 1 mm Dimensions (W×D×H) 62×12×33 cm Weight (approx.) 38kg

-

Details

Standards

- DIN 53512

PRINCIPLE

The GT-7042-RE is specifically designed to assess the rebound resilience of elastomers. This instrument applies the pendulum method, utilizing a hammer of specific mass to strike samples for assessing rebound resilience.

Wide applicability:

Well-suited for a wide range of industries such as rubber, plastics, material science, footwear, automotive, electronics, construction, medical devices, and industrial manufacturing.

Material performance assessment:

Helps manufacturers to evaluate the resilience of elastomers to impact under different scenarios to optimize material selection.

Product design improvement:

Enables designers to observe how different materials respond to impact, allowing for adjustments to be made before mass production to improve durability and safety.

Standardized test procedure:

Utilizes a standardized test procedure to provide objective test results and repeatable assessments, ensuring conformity to rebound resilience standards.

Quality assurance:

Ensuring that products consistently meet specific standards for quality, reducing defect rate in production and manufacturing.

High efficiency:

Providing simplified and efficient operation procedures to reduce both operation time and effort.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Rebound results indicator

Precisely measures and indicates the test result on a rebound scale for rebound resilience assessment.

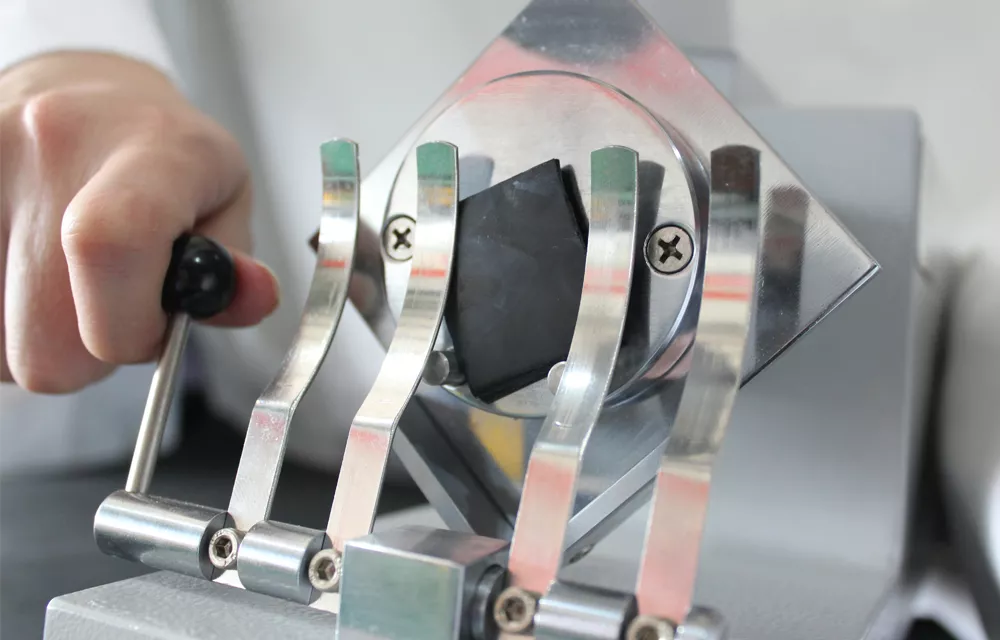

Hand-operated clamp

Utilizes manual clamping device to secure sample on the anvil, ensuring stability during testing processes.

Easy operation

Featuring easy setup and test procedures, the GT-7042-RE enables operators to conduct rebound resilience tests effortlessly.

-

Specifications

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Impact energy 0.5J Indicator scale range 0 to 100 % Minimum graduation on indicator scale 1% Length of pendulum 200±0.5 mm Drop angle 90° Impact speed 2 m/sec Range of specimen thickness 0 to 60 mm Minimum graduation on movable shaft scale 1 mm Dimensions (W×D×H) 62×12×33 cm Weight (approx.) 38kg