- The GT-7011-LHDA is specifically designed to assess the resistance of vulcanized rubber to tension fatigue when subjected to repeated flexing at high or low temperature.

- The specimen is repeated flexed under prescribed conditions until flaws cause crack growth and failure. The number of flexes at which failure occurs is then recorded.

-

Standards

- GB/T 1688-2008

- ISO 6943:2017

- BS ISO 6943:2017

Principle

The vulcanized or thermoplastics rubber is subjected to flexing at high or low temperature to cause crack growth, allowing operators to assess its behavior under repeated flexing.

Wide applicability:

Well-suited for a variety of industries such as rubber manufacturing, automotive, medical devices, electronics, and industrial manufacturing.

Authentic simulation:

Replicating the repeated stretching and deformation of vulcanized rubber in real-world applications.

Adjustable test conditions:

Allows for adjustment of various testing conditions, including stroke, frequency, and number of cycles.

Characteristics evaluation:

Helps manufacturers determine rubber characteristics under repeated stretching, such as fatigue resistance, flaws development, and crack growth.

Time and cost efficiency:

The automatic operation and efficient testing process enhance work efficiency, resulting in time and cost savings.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Temperature simulation

Simulates how vulcanized rubber materials behave at high or low temperature during real-world applications, providing reliable evaluation.

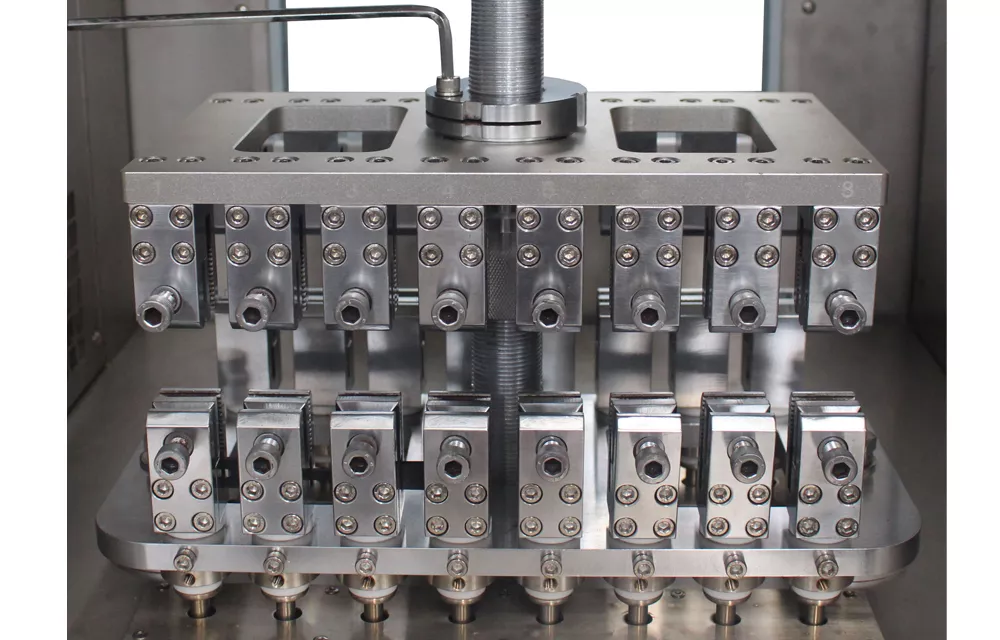

Multi-station design

Allows multiple specimens to be tested simultaneously, enhancing test efficiency without interference.

Touchscreen interface

The intuitive and user-friendly touchscreen interface allows operators to easily set parameters and control the tester.

-

左右滑動看表格

左右滑動看表格Control system PLC+HMITemp. range -50℃ to 150℃ Temp. accuracy ±2℃ Specimen capacity Dual-sided grip mechanism Count detection 16 sets Tensile strain range 10mm to 60mm (adjustable) Tensile strain accuracy ±1mm Flexing frequency 60 to 300 cpm (adjustable) Flexing frequency accuracy ±5 cpm Interior dimensions (W×D×H) 50cm×50cm×60cm Exterior dimensions (W×D×H) 90cm×140cm×180cm Weight (approx.) 612kg Power 1∮, AC 220V, 50Hz (or specify)

*Product design and specifications are subject to change without notice.

-

Details

Standards

- GB/T 1688-2008

- ISO 6943:2017

- BS ISO 6943:2017

Principle

The vulcanized or thermoplastics rubber is subjected to flexing at high or low temperature to cause crack growth, allowing operators to assess its behavior under repeated flexing.

Wide applicability:

Well-suited for a variety of industries such as rubber manufacturing, automotive, medical devices, electronics, and industrial manufacturing.

Authentic simulation:

Replicating the repeated stretching and deformation of vulcanized rubber in real-world applications.

Adjustable test conditions:

Allows for adjustment of various testing conditions, including stroke, frequency, and number of cycles.

Characteristics evaluation:

Helps manufacturers determine rubber characteristics under repeated stretching, such as fatigue resistance, flaws development, and crack growth.

Time and cost efficiency:

The automatic operation and efficient testing process enhance work efficiency, resulting in time and cost savings.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Temperature simulation

Simulates how vulcanized rubber materials behave at high or low temperature during real-world applications, providing reliable evaluation.

Multi-station design

Allows multiple specimens to be tested simultaneously, enhancing test efficiency without interference.

Touchscreen interface

The intuitive and user-friendly touchscreen interface allows operators to easily set parameters and control the tester.

-

Specifications

左右滑動看表格

左右滑動看表格Control system PLC+HMITemp. range -50℃ to 150℃ Temp. accuracy ±2℃ Specimen capacity Dual-sided grip mechanism Count detection 16 sets Tensile strain range 10mm to 60mm (adjustable) Tensile strain accuracy ±1mm Flexing frequency 60 to 300 cpm (adjustable) Flexing frequency accuracy ±5 cpm Interior dimensions (W×D×H) 50cm×50cm×60cm Exterior dimensions (W×D×H) 90cm×140cm×180cm Weight (approx.) 612kg Power 1∮, AC 220V, 50Hz (or specify)

*Product design and specifications are subject to change without notice.