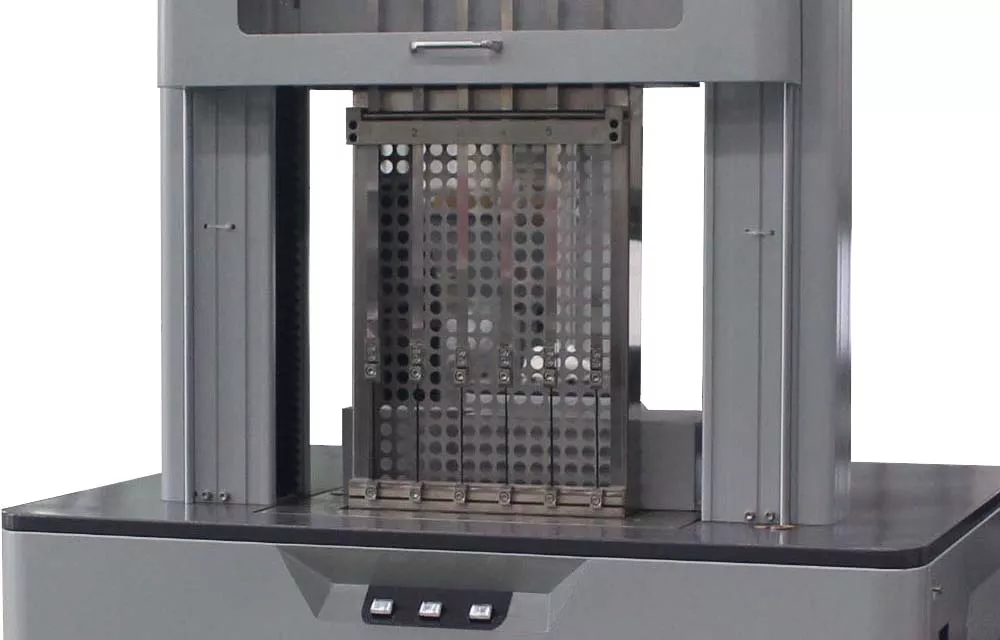

- The GT-7008-TR is specifically designed to assess the retraction characteristics of vulcanized rubber after being cooled to a low temperature.

- Specimens are first stretched at standard laboratory temperature and then cooled to a low temperature where no retraction occurs once the stretching force is removed. Subsequently, they are heated uniformly to determine the temperature at which a specified percentage of retraction takes place.

-

Standards

- ASTM D 1329-2016

- JIS K 6261-2006 7.0

- ISO 2921:2019

- GB/T 7758-2020

Principle

Specimens are first stretched at standard laboratory temperature and then cooled to a low temperature where no retraction occurs once the stretching force is removed. Subsequently, they are heated uniformly to determine the temperature at which a specified percentage of retraction takes place.

Wide material applications:

The GT-7008-TR is well suited for different types of vulcanized rubber used in various industries and applications.

High stability:

Utilizes dedicated software to precisely maintain the stability and precision during stretching and retraction.

Automatic test procedure:

The GT-7008-TR features automatic operation, enabling automatic testing procedures during stretching, cooling, and retraction. This minimizes human intervention and ensures testing accuracy.

High precision temperature control:

Equipped with high-precision temperature control system to ensure uniform heating rate during the retraction process.

Computer-controlled temperature rise:

Regulates temperature rise via dedicated software, ensuring unform rate of heating and reliable data during retraction.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Flexible test options

The dedicated software and flexible parameters settings allow operators to easily set and modify test conditions to meet a variety of testing requirements.

High efficiency

Equipped with efficient compressor cooling system to rapidly conduct cooling and meet testing requirements.

Precise control system

Utilizes an advanced control system to maintain precise control of temperature and stretching, ensuring accurate and consistent test results.

Real-time monitoring

By monitoring and recording real-time data during test processes, the GT-7008-TR offers clear insights into the temperature-retraction characteristics of vulcanized rubber.

Powerful database

Allows operators to record, search, and review test results to assist them in materials performance evaluation.

Reliability

The GT-7008-TR is built with a durable mechanical structure and sophisticated control system, ensuring precise control and long-term reliability.

-

左右滑動看表格

左右滑動看表格Temp. range Ambient temp. to -70℃ Test station 3 or 6 【select one】 Temp. resolution 0.1℃ Temp. accuracy ±2.0℃ Heating rate 1.0℃/min Cooling system Compressor cooling system Maximum elongation range 350% 【specimen length: 50mm】 Displacement resolution 0.01mm Operating system Low temperature retraction dedicated software Dimensions (W×D×H) 105×85×235 cm Power 1∮, AC 220V 50Hz (or specify)

*Product design and specifications are subject to change without notice.

-

Details

Standards

- ASTM D 1329-2016

- JIS K 6261-2006 7.0

- ISO 2921:2019

- GB/T 7758-2020

Principle

Specimens are first stretched at standard laboratory temperature and then cooled to a low temperature where no retraction occurs once the stretching force is removed. Subsequently, they are heated uniformly to determine the temperature at which a specified percentage of retraction takes place.

Wide material applications:

The GT-7008-TR is well suited for different types of vulcanized rubber used in various industries and applications.

High stability:

Utilizes dedicated software to precisely maintain the stability and precision during stretching and retraction.

Automatic test procedure:

The GT-7008-TR features automatic operation, enabling automatic testing procedures during stretching, cooling, and retraction. This minimizes human intervention and ensures testing accuracy.

High precision temperature control:

Equipped with high-precision temperature control system to ensure uniform heating rate during the retraction process.

Computer-controlled temperature rise:

Regulates temperature rise via dedicated software, ensuring unform rate of heating and reliable data during retraction.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Flexible test options

The dedicated software and flexible parameters settings allow operators to easily set and modify test conditions to meet a variety of testing requirements.

High efficiency

Equipped with efficient compressor cooling system to rapidly conduct cooling and meet testing requirements.

Precise control system

Utilizes an advanced control system to maintain precise control of temperature and stretching, ensuring accurate and consistent test results.

Real-time monitoring

By monitoring and recording real-time data during test processes, the GT-7008-TR offers clear insights into the temperature-retraction characteristics of vulcanized rubber.

Powerful database

Allows operators to record, search, and review test results to assist them in materials performance evaluation.

Reliability

The GT-7008-TR is built with a durable mechanical structure and sophisticated control system, ensuring precise control and long-term reliability.

-

Specifications

左右滑動看表格

左右滑動看表格Temp. range Ambient temp. to -70℃ Test station 3 or 6 【select one】 Temp. resolution 0.1℃ Temp. accuracy ±2.0℃ Heating rate 1.0℃/min Cooling system Compressor cooling system Maximum elongation range 350% 【specimen length: 50mm】 Displacement resolution 0.01mm Operating system Low temperature retraction dedicated software Dimensions (W×D×H) 105×85×235 cm Power 1∮, AC 220V 50Hz (or specify)

*Product design and specifications are subject to change without notice.