- The GT-7049 is designed to assess the compression set of rubber materials.

- After specimen positioned between two plates is compressed to a specific percentage of its original thickness for a given time at a given temperature, it is removed for recovery and its thickness is measured to determine the compression set.

-

Standards

- ASTM D 395

- GB/T 6669-2008

- ISO 1856:2018

Principle

The compression and deformation tester is designed to assess the compression set of rubber by subjecting specimen to constant compression for a given time at a controlled temperature. This assessment is achieved through measuring the variations in the specimen's thickness and calculating the compression set.

Wide applicability:

Well-suited for diverse industries such as rubber, material science, footwear, automotive, electronics, and industrial manufacturing.

Quality assurance:

Delivering a precise compression set solution to ensure the consistency of product performance in quality assurance.

Reliability assessment:

Replicates how rubber materials react to compression under specific environmental conditions for product reliability evaluation.

Product performance optimization:

Provides valuable information that enables manufacturers to improve and optimize products performance.

Manufacturing efficiency:

By understanding the compression set of rubber materials, manufacturers can reduce the time and costs spent during the manufacturing process and thereby enhances the manufacturing efficiency.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

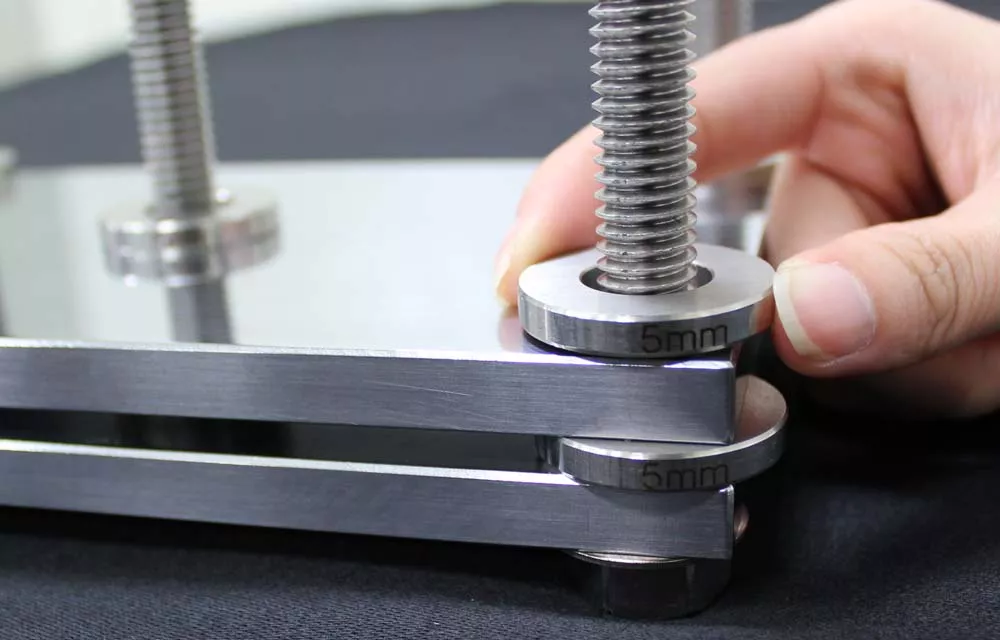

Manual operation

Utilizes spacers to adjust the space for the specific deflected height.

Durable structure

Constructed with durable and rigid structure to ensure long-term durability.

Easy-to-use

With its easy-to-use design, the GT-7049 allows straightforward operation.

-

左右滑動看表格

左右滑動看表格Model GT-7049 GT-7049-H Configuration Rectangular shaped with 5 pillars Operating temp. -70℃ to 100℃ Ambient tmep. to 300℃ Compression plate size (W×D) 200mm×120mm Dimensions (W×D×H) 208×128×135mm

*Product design and specifications are subject to change without notice.

-

Details

Standards

- ASTM D 395

- GB/T 6669-2008

- ISO 1856:2018

Principle

The compression and deformation tester is designed to assess the compression set of rubber by subjecting specimen to constant compression for a given time at a controlled temperature. This assessment is achieved through measuring the variations in the specimen's thickness and calculating the compression set.

Wide applicability:

Well-suited for diverse industries such as rubber, material science, footwear, automotive, electronics, and industrial manufacturing.

Quality assurance:

Delivering a precise compression set solution to ensure the consistency of product performance in quality assurance.

Reliability assessment:

Replicates how rubber materials react to compression under specific environmental conditions for product reliability evaluation.

Product performance optimization:

Provides valuable information that enables manufacturers to improve and optimize products performance.

Manufacturing efficiency:

By understanding the compression set of rubber materials, manufacturers can reduce the time and costs spent during the manufacturing process and thereby enhances the manufacturing efficiency.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Manual operation

Utilizes spacers to adjust the space for the specific deflected height.

Durable structure

Constructed with durable and rigid structure to ensure long-term durability.

Easy-to-use

With its easy-to-use design, the GT-7049 allows straightforward operation.

-

Specifications

左右滑動看表格

左右滑動看表格Model GT-7049 GT-7049-H Configuration Rectangular shaped with 5 pillars Operating temp. -70℃ to 100℃ Ambient tmep. to 300℃ Compression plate size (W×D) 200mm×120mm Dimensions (W×D×H) 208×128×135mm

*Product design and specifications are subject to change without notice.