- The GT-7012-D3 is designed to assess the abrasion resistance of outsoles and polymer sheet materials.

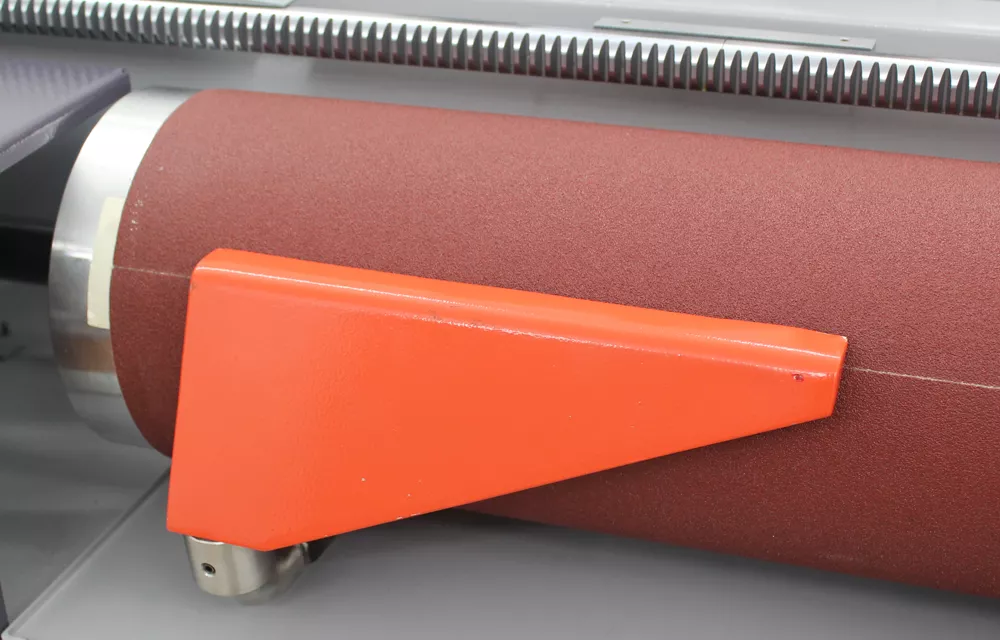

- The abrasion resistance is determined by subjecting the specimen to sliding over a sandpaper surface of specified abrasive grade.

-

Standards

- BS 903

- GB/T 9867

- ISO 4649

- JIS K6264

- SATRA TM174

- ASTM D5963

- QB/T 2884-2007

- ISO 20871:2001

- BS EN 12770:2000

Principle

The DIN abrasion resistance tester is designed specifically to determine the resistance of rubber materials such as outsole and polymer sheet materials to abrasion. The abrasion resistance is determined through subjecting specimen to sliding over a sandpaper surface with specified abrasive grade.

Wide applicability:

Well-suited for a wide variety of rubber materials including outsoles and polymer sheet.

Realistic abrasion simulation:

Simulates authentic abrasion behavior on rubber materials under real-world operational conditions, providing quick and accurate testing.

Quantitative assessment:

Offers numerical data regarding the abrasion resistance of rubber materials by measuring the amount of abrasion loss.

Quality assurance:

Assists manufacturers in maintaining consistent product quality, enhancing the overall efficiency during quality assurance processes.

Insight into abrasion loss:

Enables manufacturers to analyze, track, and compare materials characteristics by utilizing the numerical data obtained from test results.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Multiple specimen holders

Enables testing on multiple specimens simultaneously without interference.

Direct interface

The intuitive and easy to use interface allows operators to quickly learn how to operate the instrument.

Vacuum cleaner

Removes abrasive particles immediately through the equipped vacuum cleaner to ensure a clean testing environment and accurate measurement.

-

左右滑動看表格

左右滑動看表格Load 5.0±0.1N; 10.0±0.2 N Holder lateral displacement 4.2±0.04 mm/per revolution Cylindrical cylinder Φ150±0.2 mm and length of 500 mm Drum rotating speed 40±1 rpm Abrasion path 40±0.2 m (84 revolutions) Inclination angle 3°(center axis of the holder to the perpendicular in the direction of rotation) Sandpaper 60 # grain size, 1±0.2 mm average thickness, at least 400 mm Power 1∮ AC 220V (or specify)

*Product design and specifications are subject to change without notice. -

-

Details

Standards

- BS 903

- GB/T 9867

- ISO 4649

- JIS K6264

- SATRA TM174

- ASTM D5963

- QB/T 2884-2007

- ISO 20871:2001

- BS EN 12770:2000

Principle

The DIN abrasion resistance tester is designed specifically to determine the resistance of rubber materials such as outsole and polymer sheet materials to abrasion. The abrasion resistance is determined through subjecting specimen to sliding over a sandpaper surface with specified abrasive grade.

Wide applicability:

Well-suited for a wide variety of rubber materials including outsoles and polymer sheet.

Realistic abrasion simulation:

Simulates authentic abrasion behavior on rubber materials under real-world operational conditions, providing quick and accurate testing.

Quantitative assessment:

Offers numerical data regarding the abrasion resistance of rubber materials by measuring the amount of abrasion loss.

Quality assurance:

Assists manufacturers in maintaining consistent product quality, enhancing the overall efficiency during quality assurance processes.

Insight into abrasion loss:

Enables manufacturers to analyze, track, and compare materials characteristics by utilizing the numerical data obtained from test results.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Multiple specimen holders

Enables testing on multiple specimens simultaneously without interference.

Direct interface

The intuitive and easy to use interface allows operators to quickly learn how to operate the instrument.

Vacuum cleaner

Removes abrasive particles immediately through the equipped vacuum cleaner to ensure a clean testing environment and accurate measurement.

-

Specifications

左右滑動看表格

左右滑動看表格Load 5.0±0.1N; 10.0±0.2 N Holder lateral displacement 4.2±0.04 mm/per revolution Cylindrical cylinder Φ150±0.2 mm and length of 500 mm Drum rotating speed 40±1 rpm Abrasion path 40±0.2 m (84 revolutions) Inclination angle 3°(center axis of the holder to the perpendicular in the direction of rotation) Sandpaper 60 # grain size, 1±0.2 mm average thickness, at least 400 mm Power 1∮ AC 220V (or specify)

*Product design and specifications are subject to change without notice. -

Video