- The GT-7016-A2 is specifically designed to cut a precision V-notch on plastic materials.

- This instrument enables operators to shape precise V-notch on sample to meet testing requirements for impact testing.

-

Standards

- ASTM D 256

- ASTM D 6110

- GB/T 1843

- ISO 179

- ISO 180

- GB/T 1043

PRINCIPLE

The GT-7016-A2 is specifically designed to cut a precision V-notch on plastic materials. This instrument enables operators to shape precise V-notch on sample to meet testing requirements for impact testing.

Wide applicability:

Well-suited for a diverse range of industries such as aerospace, material science, construction, automotive, electronics, medical device, and industrial manufacturing.

Standard sample preparation:

The V-notch sampling machine assists operators in shaping V-notch on samples in accordance with standards.

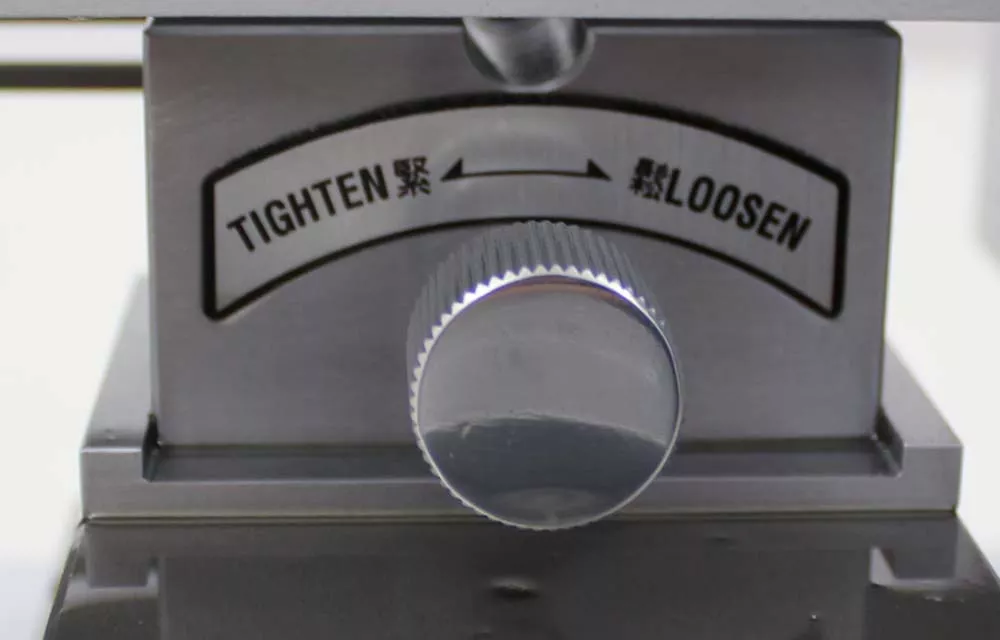

High precision control:

Utilizes high-precision control system to enhance the cutting precision, providing reliable results.

High repeatability:

Thanks to the stable mechanical structure, the V-notch sampling machine ensures precise cutting with consistent repeatability.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Easy operation

With easy setup and straightforward operation, the GT-7016-A2 enables operators to conduct V-notch cutting effortlessly.

High efficiency

Maximizes efficiency by cutting multiple specimens simultaneously, making it ideal for batch testing applications.

Time-saving solution

Reduces time and human involvement significantly especially when handling large quantities of sample.

-

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Notch angle 45±1° Notch tip radius (R)0.25mm or (R)1.0mm (optional) Dimensions (W×D×H) 30x32x26cm Weight 20kg Power 1∮, AC220V, 50/60Hz (or specify)

-

Details

Standards

- ASTM D 256

- ASTM D 6110

- GB/T 1843

- ISO 179

- ISO 180

- GB/T 1043

PRINCIPLE

The GT-7016-A2 is specifically designed to cut a precision V-notch on plastic materials. This instrument enables operators to shape precise V-notch on sample to meet testing requirements for impact testing.

Wide applicability:

Well-suited for a diverse range of industries such as aerospace, material science, construction, automotive, electronics, medical device, and industrial manufacturing.

Standard sample preparation:

The V-notch sampling machine assists operators in shaping V-notch on samples in accordance with standards.

High precision control:

Utilizes high-precision control system to enhance the cutting precision, providing reliable results.

High repeatability:

Thanks to the stable mechanical structure, the V-notch sampling machine ensures precise cutting with consistent repeatability.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Easy operation

With easy setup and straightforward operation, the GT-7016-A2 enables operators to conduct V-notch cutting effortlessly.

High efficiency

Maximizes efficiency by cutting multiple specimens simultaneously, making it ideal for batch testing applications.

Time-saving solution

Reduces time and human involvement significantly especially when handling large quantities of sample.

-

Specifications

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Notch angle 45±1° Notch tip radius (R)0.25mm or (R)1.0mm (optional) Dimensions (W×D×H) 30x32x26cm Weight 20kg Power 1∮, AC220V, 50/60Hz (or specify)