- Designed to analyze the specific volume as a function of temperature and pressure, the PVT-6000 provides significant data for optimizing the injection molding process through constant or stepwise variations in temperature and pressure.

- This instrument assists manufacturers in reducing defectes generated during injection molding process, including shrinkage, sink marks, warpage, and bubbles.

-

Principle

The PVT-6000 is specifically designed to analyze the specific volume as a function of temperature and pressure. It provides significant data for optimizing the injection molding process through constant or stepwise variations in temperature and pressure. By tracking and analyzing variations in volume, pressure, and temperature, the PVT-6000 assists manufacturers in reducing defectes generated during the injection molding process, including shrinkage, sink marks, warpage, and bubbles.

Wide applicability:

Well-suited for diverse industries such as aerospace, polymers, chemicals, medical devices, energy production, automotive, electronics, and industrial manufacturing.

High precision and accuracy:

Offers reliable density and compression-related data under various conditions, assisting manufacturers in optimizing production parameters.

Multivariate analysis:

Simultaneously measures multiple variables including pressure, volume, and temperature variations under various conditions for comprehensive performance evaluation.

Production parameters optimization:

The collected PVT data enables manufacturers to optimize the production parameters, minimizing the defects generated during manufacturing processes.

Cost-saving benefits:

By optimizing the production parameters using the PVT tester, manufacturers can significantly reduce the rejection rate, leading to cost savings during production processes.

Quality assurance:

Enables manufacturers to maintain product quality consistency and stability during manufacturing processes by predicting potential issues.

Development efficiency improvement:

The use of PVT data enables researchers to accelerate and enhance materials development, reducing the time required to launch products in the market.

-

Comprehensive measurements

The PVT-6000, with its capabilities to measures pressure, volume, and temperature simultaneously, is well-suited for a variety of materials and applications.

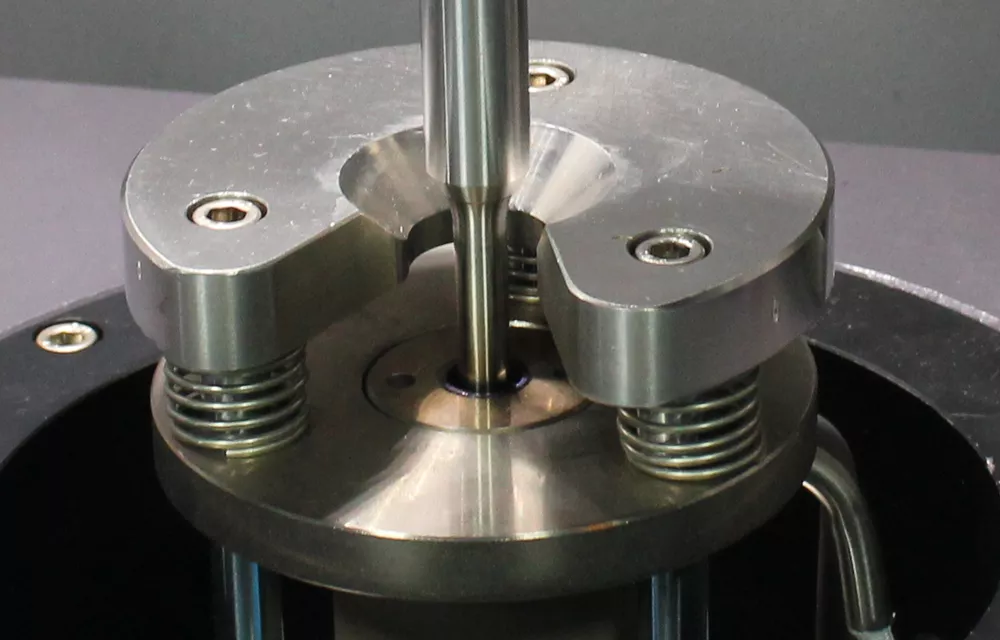

Advanced and precise sensors

Equipped with high-precision sensors, the PVT-6000 accurately measures and records real-time volume changes.

High temperature and pressure range

Adjustable test conditions with a high temperature and pressure range are provided to meet various test requirements.

Fast and steady control of test conditions

Reaches high temperature and pressure conditions quickly and maintains steady control to save operation time.

Real-time data monitoring

By providing real-time data monitoring during test processes, the PVT tester enables operators to make necessary adjustments promptly.

Powerful data analysis

Accurately captures and analyzes data, providing detailed trend analysis for a clear view of material performance.

-

左右滑動看表格

左右滑動看表格Model PVT-6000L PVT-6000HCapacity 200 bar to 1200 bar (optional: 2500 bar) 200 bar to 2500 bar Test mode Isobaric / Isothermal Temp. range Ambient temp. +10°C to 300°C Ambient temp. +10°C to 400°C Temp. accuracy <±0.3°C Temp. display resolution 0.1°C Temp. controller PID Barrel diameter 7.8 mm Piston diameter 7.76 mm 7.8 mm Barrel measuring range 10 to 23 mm Pressure accuracy ±2% Pressure controller PID Load sensor Load cell Load resolution 1/30,000 Load accuracy 0.25% Displacement detector Linear encoder system Displacement resolution 1μm Software PVT-6000 Controller 4.3" touchscreen interface Observation lamp LED Heating and cooling system Integrated heating and cooling system Heating control RKC temp. module Cooling control High-precision PID air regulating valve Power 1∮, AC 220V, 10A (or specify)

*Product design and specifications are subject to change without notice.

-

Details

Principle

The PVT-6000 is specifically designed to analyze the specific volume as a function of temperature and pressure. It provides significant data for optimizing the injection molding process through constant or stepwise variations in temperature and pressure. By tracking and analyzing variations in volume, pressure, and temperature, the PVT-6000 assists manufacturers in reducing defectes generated during the injection molding process, including shrinkage, sink marks, warpage, and bubbles.

Wide applicability:

Well-suited for diverse industries such as aerospace, polymers, chemicals, medical devices, energy production, automotive, electronics, and industrial manufacturing.

High precision and accuracy:

Offers reliable density and compression-related data under various conditions, assisting manufacturers in optimizing production parameters.

Multivariate analysis:

Simultaneously measures multiple variables including pressure, volume, and temperature variations under various conditions for comprehensive performance evaluation.

Production parameters optimization:

The collected PVT data enables manufacturers to optimize the production parameters, minimizing the defects generated during manufacturing processes.

Cost-saving benefits:

By optimizing the production parameters using the PVT tester, manufacturers can significantly reduce the rejection rate, leading to cost savings during production processes.

Quality assurance:

Enables manufacturers to maintain product quality consistency and stability during manufacturing processes by predicting potential issues.

Development efficiency improvement:

The use of PVT data enables researchers to accelerate and enhance materials development, reducing the time required to launch products in the market.

-

Features

Comprehensive measurements

The PVT-6000, with its capabilities to measures pressure, volume, and temperature simultaneously, is well-suited for a variety of materials and applications.

Advanced and precise sensors

Equipped with high-precision sensors, the PVT-6000 accurately measures and records real-time volume changes.

High temperature and pressure range

Adjustable test conditions with a high temperature and pressure range are provided to meet various test requirements.

Fast and steady control of test conditions

Reaches high temperature and pressure conditions quickly and maintains steady control to save operation time.

Real-time data monitoring

By providing real-time data monitoring during test processes, the PVT tester enables operators to make necessary adjustments promptly.

Powerful data analysis

Accurately captures and analyzes data, providing detailed trend analysis for a clear view of material performance.

-

Specifications

左右滑動看表格

左右滑動看表格Model PVT-6000L PVT-6000HCapacity 200 bar to 1200 bar (optional: 2500 bar) 200 bar to 2500 bar Test mode Isobaric / Isothermal Temp. range Ambient temp. +10°C to 300°C Ambient temp. +10°C to 400°C Temp. accuracy <±0.3°C Temp. display resolution 0.1°C Temp. controller PID Barrel diameter 7.8 mm Piston diameter 7.76 mm 7.8 mm Barrel measuring range 10 to 23 mm Pressure accuracy ±2% Pressure controller PID Load sensor Load cell Load resolution 1/30,000 Load accuracy 0.25% Displacement detector Linear encoder system Displacement resolution 1μm Software PVT-6000 Controller 4.3" touchscreen interface Observation lamp LED Heating and cooling system Integrated heating and cooling system Heating control RKC temp. module Cooling control High-precision PID air regulating valve Power 1∮, AC 220V, 10A (or specify)

*Product design and specifications are subject to change without notice.