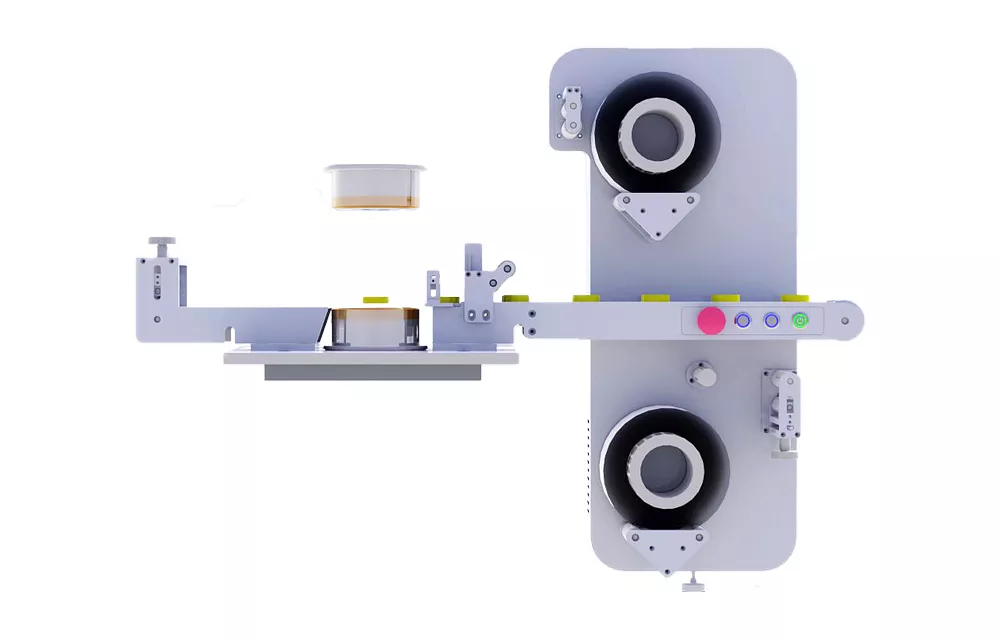

- The M-AS1 is a compact and automated system that enables automatic loading of samples in conjunction with a moving die rheometer.

- This integrated system serves as a practical auxiliary device, significantly enhancing both the efficiency and reliability of curing tests.

-

Principle

The M-AS1 is a compact and automated system that enables automatic loading of samples in conjunction with Gotech's moving die rheometer. This integrated system significantly enhances both the efficiency and reliability during curing tests.

Automatic sample loading:

Offers significant benefits that not only reduce workload but also enhance work efficiency for curing tests.

Precise processing:

Employs a high-performance processing unit to ensure accurate calculations during the sample feeding process.

Wide adaptability:

The M-AS1 is well-suited for a variety of materials and fit various applications in curing tests.

Minimizing manual intervention:

The use of automatic sample feeding system minimizes the need for manual intervention, reducing both labor costs and risk of human error.

Easy operation:

The intuitive and user-friendly interface of the M-AS1 feeding system allows operators to quickly learn how to operate the instrument.

Improved production efficiency:

With its automated workflow, the automatic sample feeding system significantly improves production efficiency, especially in batch testing.

Test results consistency:

Through automatic sample feeding, the M-AS1 ensures consistent loading operations and consistency of test results.

High reliability:

Employs reliable mechanical and electrical systems to ensure stable operation and long-term reliability.

-

Maximizing efficiency

The automatic sample loading capability not only significantly increases production efficiency but also reduces operation time.

Intervention reduction

The use of sample feeding system significantly reduces workload and minimizes risk of human error.

Easy operation

The intuitive and easy to use interface allows operators to quickly learn how to operate the instrument.

-

左右滑動看表格

左右滑動看表格Specimen capacity 6 pcs Specimen thickness 5 mm (or customized) Cellophane size 180 × 75 × 100 mm (outer dia. × inner dia. × height); T=0.025 mm Cellophane and specimen loading Motorized + Pneumatic Specimen positioning system Optical detector Cellophane replacement notification Auto-detection and buzzer alarm Specimen placement notification Auto-detection and buzzer alarm Cellophane tension adjustment Adjustable Frequency Adjustable Required air source 5 kg/cm2 Dimensions Approx. 1050mm(W) x 250mm(D) x 800mm(L)

*Product design and specifications are subject to change without notice. -

-

Details

Principle

The M-AS1 is a compact and automated system that enables automatic loading of samples in conjunction with Gotech's moving die rheometer. This integrated system significantly enhances both the efficiency and reliability during curing tests.

Automatic sample loading:

Offers significant benefits that not only reduce workload but also enhance work efficiency for curing tests.

Precise processing:

Employs a high-performance processing unit to ensure accurate calculations during the sample feeding process.

Wide adaptability:

The M-AS1 is well-suited for a variety of materials and fit various applications in curing tests.

Minimizing manual intervention:

The use of automatic sample feeding system minimizes the need for manual intervention, reducing both labor costs and risk of human error.

Easy operation:

The intuitive and user-friendly interface of the M-AS1 feeding system allows operators to quickly learn how to operate the instrument.

Improved production efficiency:

With its automated workflow, the automatic sample feeding system significantly improves production efficiency, especially in batch testing.

Test results consistency:

Through automatic sample feeding, the M-AS1 ensures consistent loading operations and consistency of test results.

High reliability:

Employs reliable mechanical and electrical systems to ensure stable operation and long-term reliability.

-

Features

Maximizing efficiency

The automatic sample loading capability not only significantly increases production efficiency but also reduces operation time.

Intervention reduction

The use of sample feeding system significantly reduces workload and minimizes risk of human error.

Easy operation

The intuitive and easy to use interface allows operators to quickly learn how to operate the instrument.

-

Specifications

左右滑動看表格

左右滑動看表格Specimen capacity 6 pcs Specimen thickness 5 mm (or customized) Cellophane size 180 × 75 × 100 mm (outer dia. × inner dia. × height); T=0.025 mm Cellophane and specimen loading Motorized + Pneumatic Specimen positioning system Optical detector Cellophane replacement notification Auto-detection and buzzer alarm Specimen placement notification Auto-detection and buzzer alarm Cellophane tension adjustment Adjustable Frequency Adjustable Required air source 5 kg/cm2 Dimensions Approx. 1050mm(W) x 250mm(D) x 800mm(L)

*Product design and specifications are subject to change without notice. -

Video