- The UN-7001-LAC is specifically designed to conduct tensile, compression, and bending tests on a wide variety of materials, providing precise reliable measurements to evaluate their mechanical properties.

- This machine features an efficient motor-driven hydraulic system, high-precision load cell, and dedicated testing software, delivering exceptional accuracy and control throughout the testing process.

-

PRINCIPLE

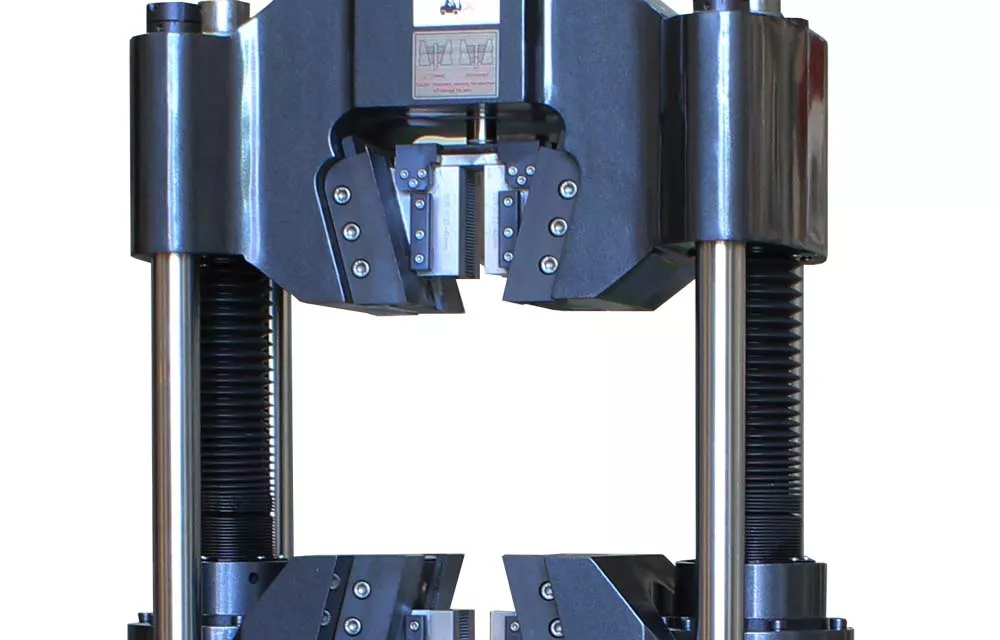

The UN-7001-LAC is a sophisticated machine designed to provide valuable insights into material mechanical properties. Its durable 6-column structure reliably supports a variety of tests including tension, compression, and bending. With a high-precision load cell and powerful testing software, this machine achieves remarkable accuracy in measuring stress and strain, enabling comprehensive assessment of material characteristics such as elasticity, plasticity, stress-strain behavior, and breaking point.

Wide applicability:

Applicable to industries such as aerospace, petroleum exploration, road and bridge construction, railways, automotive, energy, coal, natural gas, and industrial manufacturing.

Customized test methods:

Gotech's Leader II testing software offers a range of test methods in accordance with GB, ASTM, and ISO, along with adjustable user permissions to meet various requirements.

Optimizing product strength and reliability:

Provides critical insight into product resistance to expected loads and deformation, supporting manufacturers in maintaining superior product quality and reliability.

Materials selection analysis:

Supports operators in making objective comparisons of different materials' performance to meet specific requirements.

Quality assurance and control:

Offers standardized test procedure conforming to industry standards, ensuring the accuracy and efficiency of quality assurance.

Manufacturing process enhancement:

Collects valuable data on material performance to enhance the manufacturing process and minimize defects during production.

New product development and innovation:

Assists manufacturers in testing new products and materials to verify they meet expected performance.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

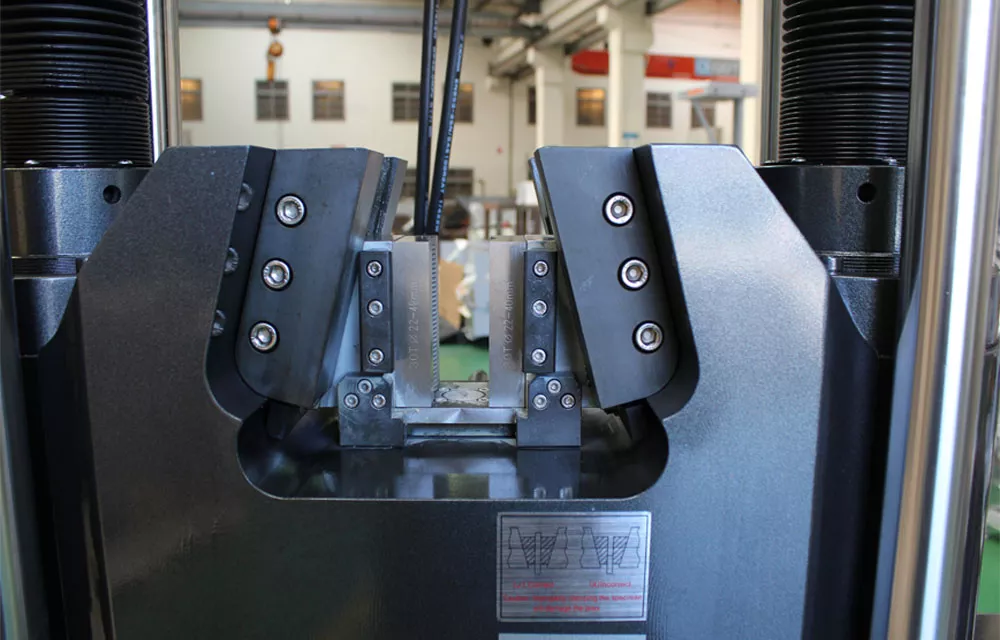

Open-ended structure

Allowing for quick and easy specimen installation, accommodating a variety of specimen sizes and shapes.

High-precision curve measurement

Utilizes high-precision feedback mechanisms to achieve precise curve plotting throughout the testing process.

Comprehensive testing capability

Simulates realistic stress tests, including tension, compression, and bending on materials, providing valuable insight into material performance.

Flexible parameter configuration

Gotech's dedicated testing software offers a broad range of parameter options, enabling operators to customize test conditions according to their specific requirements.

Live data display

Displays data in real-time, including load and displacement so that operators can monitor the performance of specimens immediately.

Powerful database

Enables operators to store, manage, and efficiently search test data, facilitating the analysis of material performance.

-

左右滑動看表格

左右滑動看表格Model UN-7001-LAC200 UN-7001-LAC100 UN-7001-LAC50 UN-7001-LAC30 UN-7001-LAC20 UN-7001-LAC10 Capacity (ton) 200tf 100tf 50tf 30tf 20tf 10tf Test speed (mm/min) (without load) 1 to 65 1 to 70 1 to 70 1 to 90 1 to 90 1 to 90 Display and control Dedicated testing software Dedicated testing software Dedicated testing software Dedicated testing software Dedicated testing software Dedicated testing software Load amplification ratio Rangeless Rangeless Rangeless Rangeless Rangeless Rangeless Load resolution 1/500,000 Load accuracy ±1% Drive system Hydraulic system Tensile testing Max. effective space (mm)

(excl. ram stroke)520 370 370 360 360 360 Rod specimen dia. (mm) 12 to 85 13 to 75 12 to 50 10 to 40 10 to 40 10 to 40 Plate specimen size (mm)

(thickness×width)85x110 70x90 50x80 40x60 40x60 40x60 Compression testing Effective space (mm)

(incl. ram stroke)750 590 590 560 560 560 Diameter of compression platen (mm) 200 170 120 100 100 100 Transverse bend testing Effective space (mm)

(with installed supports and punch)

(incl. ram stroke)230 190 220 200 200 200 Supports Max. space between fulcrums (mm) 790 340 390 390 390 390 Fulcrum size (mm)

(dia.×width)30x210 30x145 30x145 30x145 30x145 30x145 Punch Punch radius (mm) R35 R22 R22 R16 R16 R16 Punch width (mm) 200 160 120 100 100 100 Ram stroke (mm) 230 220 220 200 200 200 Number of pillars 6 6 6 6 6 6 Effective space between columns (mm) 630 450 450 410 410 410 Crosshead drive system Hydraulic-driven Hydraulic-driven Hydraulic-driven Hydraulic-driven Hydraulic-driven Hydraulic-driven Crosshead speed (mm/min) 300+/-10% 300+/-10% 300+/-10% 300+/-10% 300+/-10% 300+/-10% Dimensions (W×D×H) Main unit (mm) 1320X1080X3150 1060X830X2600 950X750X2300 850X660X1950 850X660X1950 850X660X1950 Control unit (mm) 1270X760X990 1270X760X990 1270X760X990 1270X760X990 1270X760X990 1270X760X990 Standard accessories Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Optional accessories Bending jigs, compression platens Bending jigs, compression platens Bending jigs, compression platens Bending jigs, compression platens Bending jigs, compression platens Bending jigs, compression platens

*Product design and specifications are subject to change without notice.

-

Details

PRINCIPLE

The UN-7001-LAC is a sophisticated machine designed to provide valuable insights into material mechanical properties. Its durable 6-column structure reliably supports a variety of tests including tension, compression, and bending. With a high-precision load cell and powerful testing software, this machine achieves remarkable accuracy in measuring stress and strain, enabling comprehensive assessment of material characteristics such as elasticity, plasticity, stress-strain behavior, and breaking point.

Wide applicability:

Applicable to industries such as aerospace, petroleum exploration, road and bridge construction, railways, automotive, energy, coal, natural gas, and industrial manufacturing.

Customized test methods:

Gotech's Leader II testing software offers a range of test methods in accordance with GB, ASTM, and ISO, along with adjustable user permissions to meet various requirements.

Optimizing product strength and reliability:

Provides critical insight into product resistance to expected loads and deformation, supporting manufacturers in maintaining superior product quality and reliability.

Materials selection analysis:

Supports operators in making objective comparisons of different materials' performance to meet specific requirements.

Quality assurance and control:

Offers standardized test procedure conforming to industry standards, ensuring the accuracy and efficiency of quality assurance.

Manufacturing process enhancement:

Collects valuable data on material performance to enhance the manufacturing process and minimize defects during production.

New product development and innovation:

Assists manufacturers in testing new products and materials to verify they meet expected performance.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Open-ended structure

Allowing for quick and easy specimen installation, accommodating a variety of specimen sizes and shapes.

High-precision curve measurement

Utilizes high-precision feedback mechanisms to achieve precise curve plotting throughout the testing process.

Comprehensive testing capability

Simulates realistic stress tests, including tension, compression, and bending on materials, providing valuable insight into material performance.

Flexible parameter configuration

Gotech's dedicated testing software offers a broad range of parameter options, enabling operators to customize test conditions according to their specific requirements.

Live data display

Displays data in real-time, including load and displacement so that operators can monitor the performance of specimens immediately.

Powerful database

Enables operators to store, manage, and efficiently search test data, facilitating the analysis of material performance.

-

Specifications

左右滑動看表格

左右滑動看表格Model UN-7001-LAC200 UN-7001-LAC100 UN-7001-LAC50 UN-7001-LAC30 UN-7001-LAC20 UN-7001-LAC10 Capacity (ton) 200tf 100tf 50tf 30tf 20tf 10tf Test speed (mm/min) (without load) 1 to 65 1 to 70 1 to 70 1 to 90 1 to 90 1 to 90 Display and control Dedicated testing software Dedicated testing software Dedicated testing software Dedicated testing software Dedicated testing software Dedicated testing software Load amplification ratio Rangeless Rangeless Rangeless Rangeless Rangeless Rangeless Load resolution 1/500,000 Load accuracy ±1% Drive system Hydraulic system Tensile testing Max. effective space (mm)

(excl. ram stroke)520 370 370 360 360 360 Rod specimen dia. (mm) 12 to 85 13 to 75 12 to 50 10 to 40 10 to 40 10 to 40 Plate specimen size (mm)

(thickness×width)85x110 70x90 50x80 40x60 40x60 40x60 Compression testing Effective space (mm)

(incl. ram stroke)750 590 590 560 560 560 Diameter of compression platen (mm) 200 170 120 100 100 100 Transverse bend testing Effective space (mm)

(with installed supports and punch)

(incl. ram stroke)230 190 220 200 200 200 Supports Max. space between fulcrums (mm) 790 340 390 390 390 390 Fulcrum size (mm)

(dia.×width)30x210 30x145 30x145 30x145 30x145 30x145 Punch Punch radius (mm) R35 R22 R22 R16 R16 R16 Punch width (mm) 200 160 120 100 100 100 Ram stroke (mm) 230 220 220 200 200 200 Number of pillars 6 6 6 6 6 6 Effective space between columns (mm) 630 450 450 410 410 410 Crosshead drive system Hydraulic-driven Hydraulic-driven Hydraulic-driven Hydraulic-driven Hydraulic-driven Hydraulic-driven Crosshead speed (mm/min) 300+/-10% 300+/-10% 300+/-10% 300+/-10% 300+/-10% 300+/-10% Dimensions (W×D×H) Main unit (mm) 1320X1080X3150 1060X830X2600 950X750X2300 850X660X1950 850X660X1950 850X660X1950 Control unit (mm) 1270X760X990 1270X760X990 1270X760X990 1270X760X990 1270X760X990 1270X760X990 Standard accessories Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Jaw faces for plate and rod specimens Optional accessories Bending jigs, compression platens Bending jigs, compression platens Bending jigs, compression platens Bending jigs, compression platens Bending jigs, compression platens Bending jigs, compression platens

*Product design and specifications are subject to change without notice.