- The U33-LDE employs the image tracking algorithm and utilizes a dual camera system to analyze both the upper and lower marks on the sample, ensuring precise tracking of all colors from the beginning to the end of the test.

- Featuring specialized image processing technique, this non-contact extensometer can eliminate the reflection from other components (e.g., grips and the main unit) outside the sample.

-

Principle

The U33-LDE non-contact extensometer employs the image tracking algorithm and utilizes a dual camera system to analyze both the upper and lower marks on the sample, ensuring precise tracking of all colors during a tensile test.

Image tracking algorithm :

Utilizes advanced image tracking algorithm to ensure precise tracking of marks on the sample.

Specialized image processing technique :

Eliminates the reflection from other components (e.g., grips or machine), ensuring the measurement stability.

Non-contact measurement :

The non-contact design eliminates the risk of causing damage or interference to the sample during the measurement.

Dynamic real-time tracking :

Provides dynamic real-time tracking with immediate insights, precise monitoring, and enhanced efficiency.

Adaptability :

Accommodates diverse conditions and environments, ensuring accurate and precise measurements.

-

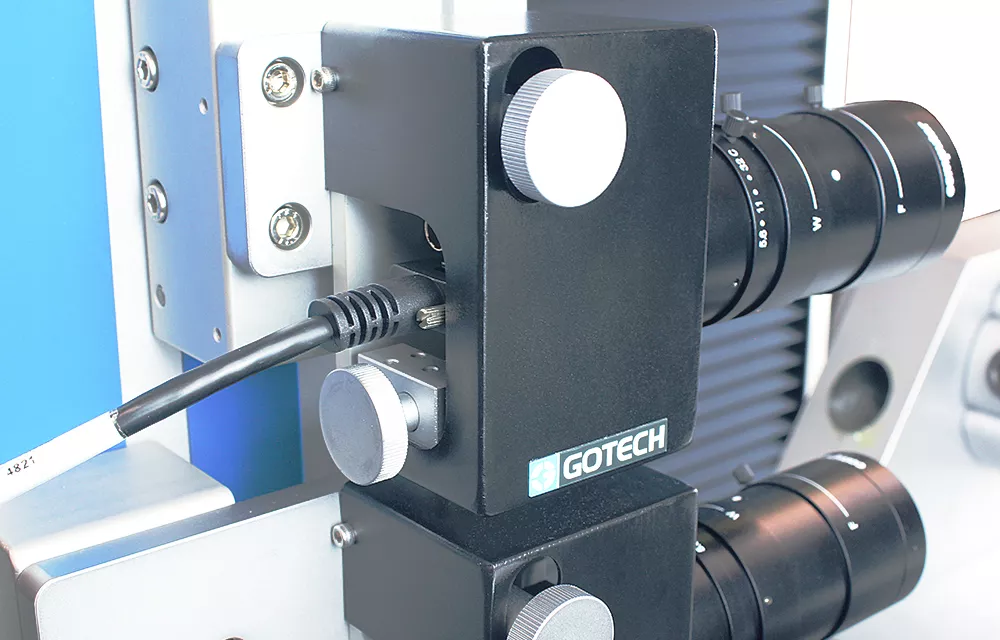

Dual camera configuration

Monitor and capture images from various perspectives, ensuring comprehensive analysis and flexibility.

High accuracy and precision

Offers high accuracy and precise measurement on both the upper and lower marks on the sample through its advanced image tracking algorithm.

Advanced color detection

Carries out precise measurements across different colors and delivers consistent test results without exception.

-

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Compatible model AI-3000, AI-5000, AI-7000 Effective stroke Max. 700 mm Gauge length 10 mm or above (adjustable) Tracking speed 0.001~1000 mm/min Stroke resolution 0.0005 mm Tracking method CCD image processing algorithm and servo control system Marking color Contrasting color to sample Specimen color All colors -

-

Details

Principle

The U33-LDE non-contact extensometer employs the image tracking algorithm and utilizes a dual camera system to analyze both the upper and lower marks on the sample, ensuring precise tracking of all colors during a tensile test.

Image tracking algorithm :

Utilizes advanced image tracking algorithm to ensure precise tracking of marks on the sample.

Specialized image processing technique :

Eliminates the reflection from other components (e.g., grips or machine), ensuring the measurement stability.

Non-contact measurement :

The non-contact design eliminates the risk of causing damage or interference to the sample during the measurement.

Dynamic real-time tracking :

Provides dynamic real-time tracking with immediate insights, precise monitoring, and enhanced efficiency.

Adaptability :

Accommodates diverse conditions and environments, ensuring accurate and precise measurements.

-

Features

Dual camera configuration

Monitor and capture images from various perspectives, ensuring comprehensive analysis and flexibility.

High accuracy and precision

Offers high accuracy and precise measurement on both the upper and lower marks on the sample through its advanced image tracking algorithm.

Advanced color detection

Carries out precise measurements across different colors and delivers consistent test results without exception.

-

Specifications

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Compatible model AI-3000, AI-5000, AI-7000 Effective stroke Max. 700 mm Gauge length 10 mm or above (adjustable) Tracking speed 0.001~1000 mm/min Stroke resolution 0.0005 mm Tracking method CCD image processing algorithm and servo control system Marking color Contrasting color to sample Specimen color All colors -

Video