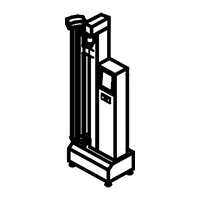

- The GT-7010-D2E is a single column and floor type tensile strength tester. Equipped with high precision micro-computer control system and stroke display feature, it fulfills the testing needs for various strength tests.

- This machine is capable of performing a variety of tests including tension, compression, bending, tearing, peeling, shearing, and bonding across diverse industries, such as rubber, plastics, footwear, leather, cables, and packaging, with a focus on mid to low range test loads.

-

Principle

The GT-7010-D2E is equipped with a high precision micro-computer control system, making it a versatile and easy to operate tensile strength tester. This machine offers a diverse range of tests through its compatibility with various tailored grips, including tension, elongation, tearing, bonding, peeling, shearing, and adhesion on materials such as rubber, plastics, elastomers, textiles, metals, and cardboards. In essence, the GT-7010-D2E series plays a significant role in materials testing by providing invaluable analysis of mechanical properties across different materials, semi-finished products, and finished products.

Wide applicability across diverse industries :

Suitable for diverse industries such as aerospace, construction, railway, mining, material science, automotive, medical devices, and industrial manufacturing.

Improving the strength and reliability of products:

Provides insight into product resistance to expected loads and deformation.

Materials selection analysis:

Assists operators in comparing the performance of various materials to fulfill specific requirements for materials selection.

Quality assurance and control:

Offers standardized test procedure conforming to standards to ensure the accuracy of quality assurance.

Manufacturing process enhancement:

Provides valuable data to enhance manufacturing process and minimize defects.

Product research and innovation:

Ensures the new products or materials can meet the expected performance.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

Cost-effective solution :

The GT-7010-D2E is an ideal choice for a limited budget comparing with advanced universal testing machine.

-

Micro-computer control system

Featuring an advanced micro-computer control system, the GT-7010-D2E ensures precise control during tensile testing.

Versatile Testing Capability

Simulates realistic stress tests, including tension, compression, bending, and shearing on materials, providing valuable insight into the materials performance.

Compact single-column design

The GT-7010-D2E's compact and space-efficient design makes it an excellent choice for limited space.

Intuitive operating interface

The user-friendly design of the interface ensures easy readability and operation, allowing operators to conduct test more effectively

Test results recorder

Automatically records test results upon completion of test, providing operators with valuable information for analysis.

Enhanced safety features

Equipped with advanced safety devices, including limit switches and an emergency stop, ensuring secure operations and protecting both users and equipment.

-

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Sensor LOAD CELL Display device U26 indicator Capacity 100,200,500 N ; 1,2, kN optional Unit (changeable) kgf、gf、tonf、lbf、N、kN Load resolution 1 / 50,000 Load accuracy ±0.5% Stoke accuracy 0.01 mm Test speed 5 ~ 500 mm/min adjustable Motor AC servo motor Speed control method Closed-loop speed control Indicator displaying elongation value 、test value 、breaking value 、max. value Dimension (W×D×H) 55×35×182 cm Power 1∮ AC 220V 5A (or specified by user)

-

Details

Principle

The GT-7010-D2E is equipped with a high precision micro-computer control system, making it a versatile and easy to operate tensile strength tester. This machine offers a diverse range of tests through its compatibility with various tailored grips, including tension, elongation, tearing, bonding, peeling, shearing, and adhesion on materials such as rubber, plastics, elastomers, textiles, metals, and cardboards. In essence, the GT-7010-D2E series plays a significant role in materials testing by providing invaluable analysis of mechanical properties across different materials, semi-finished products, and finished products.

Wide applicability across diverse industries :

Suitable for diverse industries such as aerospace, construction, railway, mining, material science, automotive, medical devices, and industrial manufacturing.

Improving the strength and reliability of products:

Provides insight into product resistance to expected loads and deformation.

Materials selection analysis:

Assists operators in comparing the performance of various materials to fulfill specific requirements for materials selection.

Quality assurance and control:

Offers standardized test procedure conforming to standards to ensure the accuracy of quality assurance.

Manufacturing process enhancement:

Provides valuable data to enhance manufacturing process and minimize defects.

Product research and innovation:

Ensures the new products or materials can meet the expected performance.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

Cost-effective solution :

The GT-7010-D2E is an ideal choice for a limited budget comparing with advanced universal testing machine.

-

Features

Micro-computer control system

Featuring an advanced micro-computer control system, the GT-7010-D2E ensures precise control during tensile testing.

Versatile Testing Capability

Simulates realistic stress tests, including tension, compression, bending, and shearing on materials, providing valuable insight into the materials performance.

Compact single-column design

The GT-7010-D2E's compact and space-efficient design makes it an excellent choice for limited space.

Intuitive operating interface

The user-friendly design of the interface ensures easy readability and operation, allowing operators to conduct test more effectively

Test results recorder

Automatically records test results upon completion of test, providing operators with valuable information for analysis.

Enhanced safety features

Equipped with advanced safety devices, including limit switches and an emergency stop, ensuring secure operations and protecting both users and equipment.

-

Specifications

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Sensor LOAD CELL Display device U26 indicator Capacity 100,200,500 N ; 1,2, kN optional Unit (changeable) kgf、gf、tonf、lbf、N、kN Load resolution 1 / 50,000 Load accuracy ±0.5% Stoke accuracy 0.01 mm Test speed 5 ~ 500 mm/min adjustable Motor AC servo motor Speed control method Closed-loop speed control Indicator displaying elongation value 、test value 、breaking value 、max. value Dimension (W×D×H) 55×35×182 cm Power 1∮ AC 220V 5A (or specified by user)