- The GT-GS-GBT is specifically designed to measure the hardness of shoe outsoles and heels.

- By vertically pressing a shore durometer under specific conditions against the specimen, the outsole hardness can be determined.

-

Standards

- GB/T 3903.4-2017

Principle

The GT-GS-GBT is specifically designed to assess the hardness of shoe outsoles and heels using a shore durometer. By vertically pressing the shore durometer under specific conditions against the specimen, the outsole hardness can be determined.

Material applications:

Well-suited to assess the hardness of shoe outsoles and heels, enabling manufacturers to evaluate the durability and comfort of footwear products.

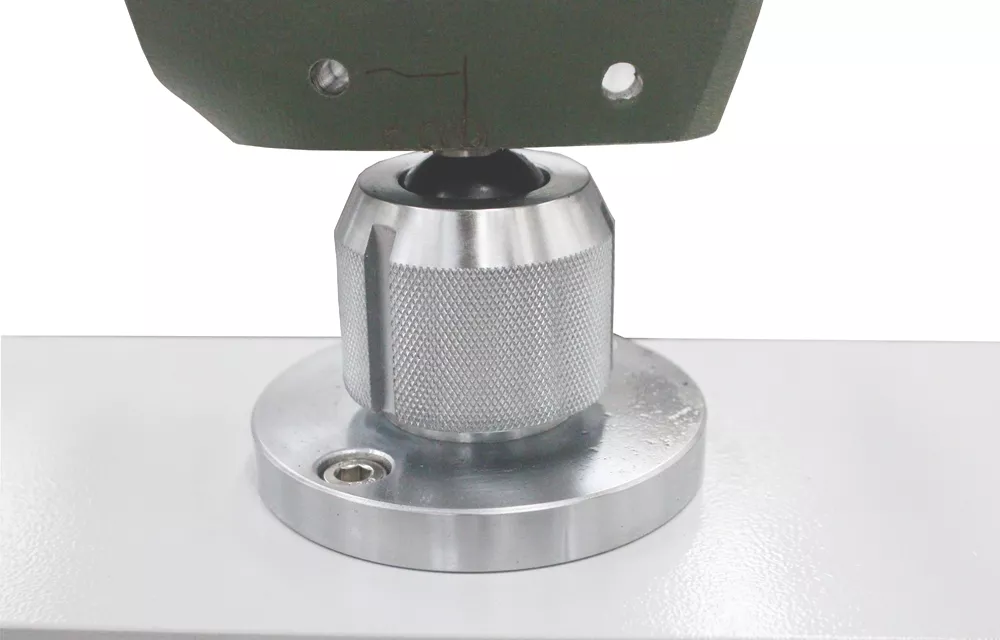

Prescribed probe shape:

Applies a durometer probe with a specific shape prescribed by specific standards, ensuring accurate and repeatable test results.

Quality assurance:

Supports manufacturers in verifying the hardness of shoe outsoles and heels during the quality assurance processes

Production process control:

Assists manufacturers in controlling the production processes to ensure that each produced footwear product meets the hardness requirements.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Real-time monitoring

The easy to ready display enables operators to directly monitor test results of specimen hardness.

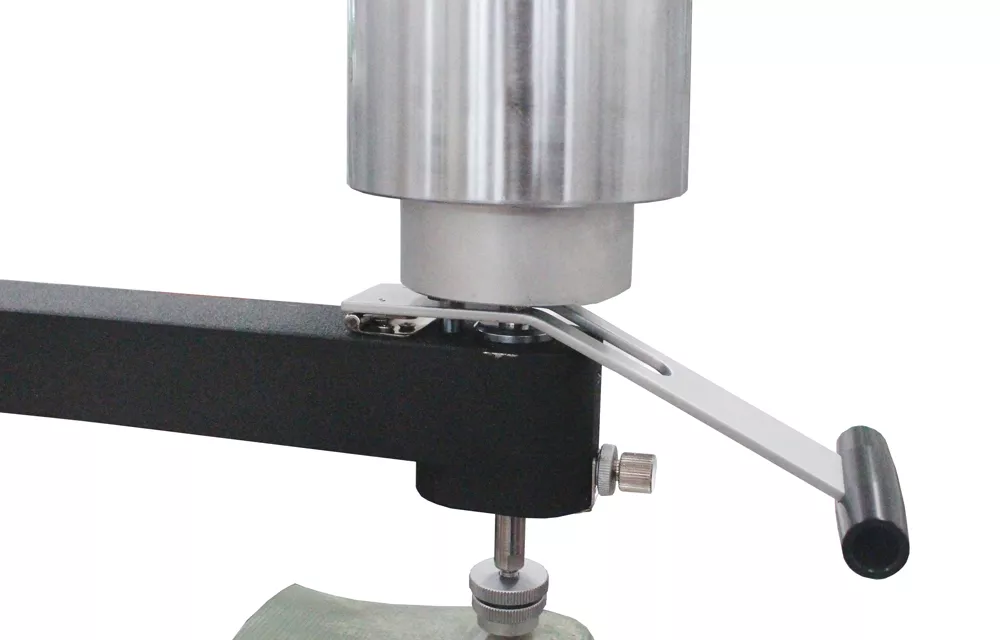

Easy operation

With easy setup and straightforward operation, the GT-GS-GBT allows operators to quickly and precisely perform the hardness assessment.

Rapid assessment

Enables operators to quickly measure material hardness, enhancing work efficiency during production processes.

-

左右滑動看表格

左右滑動看表格Load 1kg (basic load), 5kg (1kg basic load + 4kg optional weight) Workbench forward-backward adjustment range ±60mm Workbench lateral adjustment range ±60mm Dimensions (approx.) 50 cm×60 cm×86 cm

*Product design and specifications are subject to change without notice.

-

Details

Standards

- GB/T 3903.4-2017

Principle

The GT-GS-GBT is specifically designed to assess the hardness of shoe outsoles and heels using a shore durometer. By vertically pressing the shore durometer under specific conditions against the specimen, the outsole hardness can be determined.

Material applications:

Well-suited to assess the hardness of shoe outsoles and heels, enabling manufacturers to evaluate the durability and comfort of footwear products.

Prescribed probe shape:

Applies a durometer probe with a specific shape prescribed by specific standards, ensuring accurate and repeatable test results.

Quality assurance:

Supports manufacturers in verifying the hardness of shoe outsoles and heels during the quality assurance processes

Production process control:

Assists manufacturers in controlling the production processes to ensure that each produced footwear product meets the hardness requirements.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Real-time monitoring

The easy to ready display enables operators to directly monitor test results of specimen hardness.

Easy operation

With easy setup and straightforward operation, the GT-GS-GBT allows operators to quickly and precisely perform the hardness assessment.

Rapid assessment

Enables operators to quickly measure material hardness, enhancing work efficiency during production processes.

-

Specifications

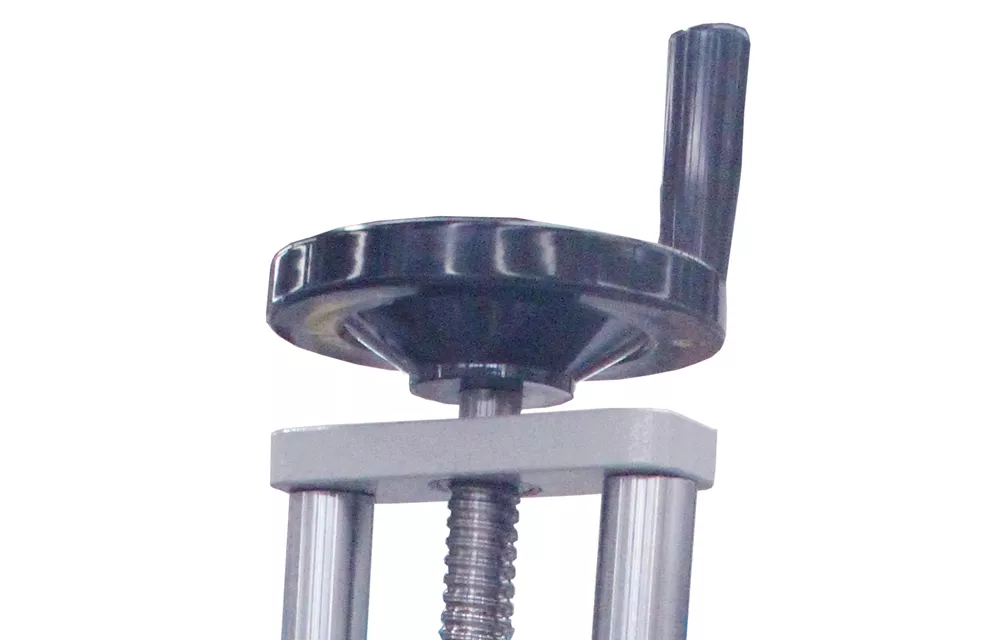

左右滑動看表格

左右滑動看表格Load 1kg (basic load), 5kg (1kg basic load + 4kg optional weight) Workbench forward-backward adjustment range ±60mm Workbench lateral adjustment range ±60mm Dimensions (approx.) 50 cm×60 cm×86 cm

*Product design and specifications are subject to change without notice.