- The GT-7073-GB2 is specifically designed to measure the stiffness of various shoe uppers.

- By reciprocally moving the cylinders closer to each other with mounted specimen at a specified stroke and measuring the corresponding force, the stiffness of the specimen can be calculated.

-

Standards

- GB/T 3903.2

- ISO 5403-1

PRINCIPLE

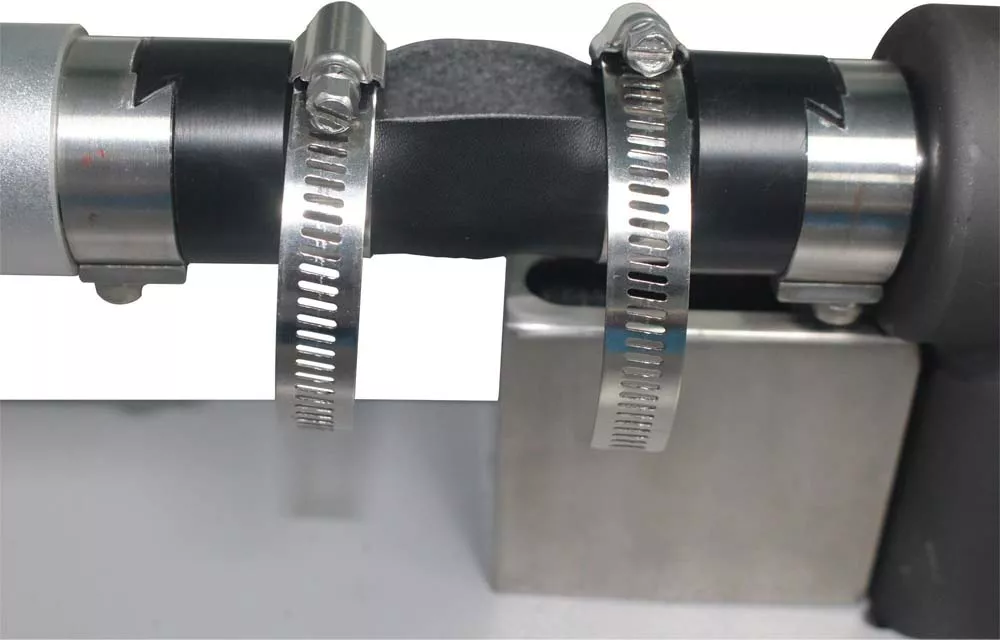

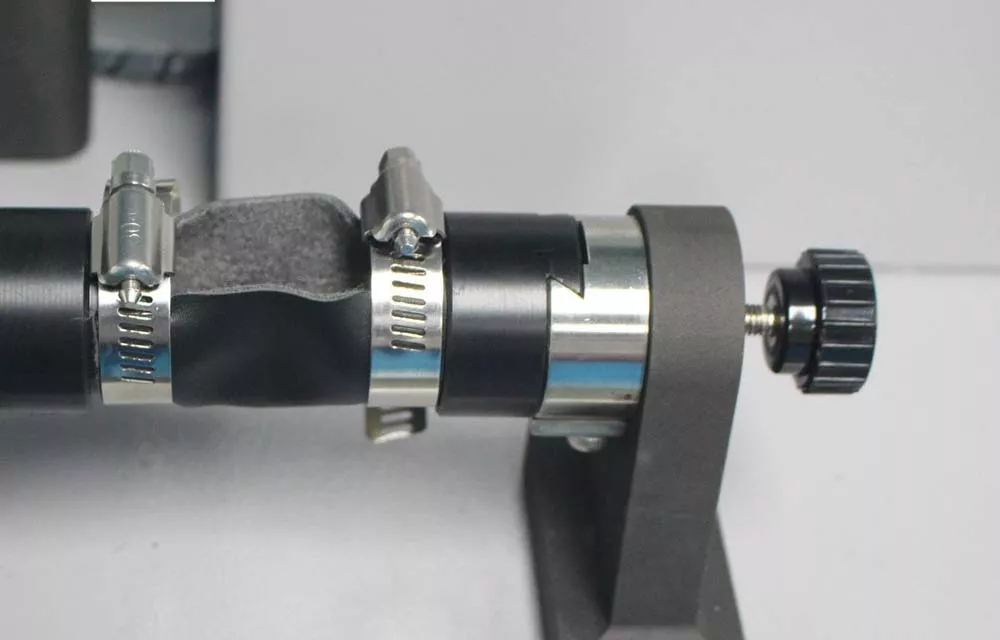

The leather stiffness tester is specifically designed to measure the stiffness of various shoe uppers. To perform the stiffness test, the rectangular specimen is bent to form a trough, and its two ends are attached to the cylinders using ring clamps. While the cylinders are moved closer to each other at a specified stroke, the required force is measured.

Wide applicability:

Well-suited for assessing the stiffness of uppers across various shoe types.

High-precision measurement:

Recording the data of force values upon test completion to support the evaluation of specimen stiffness.

Cost-saving:

Minimizes manual intervention using automatic data capture and touchscreen operation, significantly reducing costs and increasing efficiency during production.

Quality assurance:

Assists manufacturers in verifying that their footwear products meet specific stiffness standards for quality assurance.

Optimization in product development:

Helps manufacturers analyze how various materials and designs impact the stiffness of the shoe upper, supporting the optimization of new product performance.

Effective material selection:

The leather stiffness tester is an ideal solution for assessing the stiffness of leather and synthetic leather materials, providing valuable data for optimizing material selection.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Specimen clamp station

Equipped with cylindrical specimen clamping station, allowing for easy and quick specimen installation.

Automatic data capture

The touchscreen design enables user to effortlessly input parameters such as stroke, speed, and force. The real-time status can be monitored during testing.

High-precision sensor

With a high-precision load cell, the force corresponding to the specified stroke can be accurately measured, allowing for precise calculations of specimen stiffness.

-

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Sensor Load Cell Capacity 500N (or specify) Diameter of clamping cylinder φ30±0.5mm Maximum distance between clamping cylinders 40±0.5mm Dimensions (approx.) (W×D×H) 67×26×34cm Power 1∮ AC 220V 50HZ (or specify)

-

Details

Standards

- GB/T 3903.2

- ISO 5403-1

PRINCIPLE

The leather stiffness tester is specifically designed to measure the stiffness of various shoe uppers. To perform the stiffness test, the rectangular specimen is bent to form a trough, and its two ends are attached to the cylinders using ring clamps. While the cylinders are moved closer to each other at a specified stroke, the required force is measured.

Wide applicability:

Well-suited for assessing the stiffness of uppers across various shoe types.

High-precision measurement:

Recording the data of force values upon test completion to support the evaluation of specimen stiffness.

Cost-saving:

Minimizes manual intervention using automatic data capture and touchscreen operation, significantly reducing costs and increasing efficiency during production.

Quality assurance:

Assists manufacturers in verifying that their footwear products meet specific stiffness standards for quality assurance.

Optimization in product development:

Helps manufacturers analyze how various materials and designs impact the stiffness of the shoe upper, supporting the optimization of new product performance.

Effective material selection:

The leather stiffness tester is an ideal solution for assessing the stiffness of leather and synthetic leather materials, providing valuable data for optimizing material selection.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Specimen clamp station

Equipped with cylindrical specimen clamping station, allowing for easy and quick specimen installation.

Automatic data capture

The touchscreen design enables user to effortlessly input parameters such as stroke, speed, and force. The real-time status can be monitored during testing.

High-precision sensor

With a high-precision load cell, the force corresponding to the specified stroke can be accurately measured, allowing for precise calculations of specimen stiffness.

-

Specifications

左右滑動看表格

左右滑動看表格

*Product design and specifications are subject to change without notice.Sensor Load Cell Capacity 500N (or specify) Diameter of clamping cylinder φ30±0.5mm Maximum distance between clamping cylinders 40±0.5mm Dimensions (approx.) (W×D×H) 67×26×34cm Power 1∮ AC 220V 50HZ (or specify)