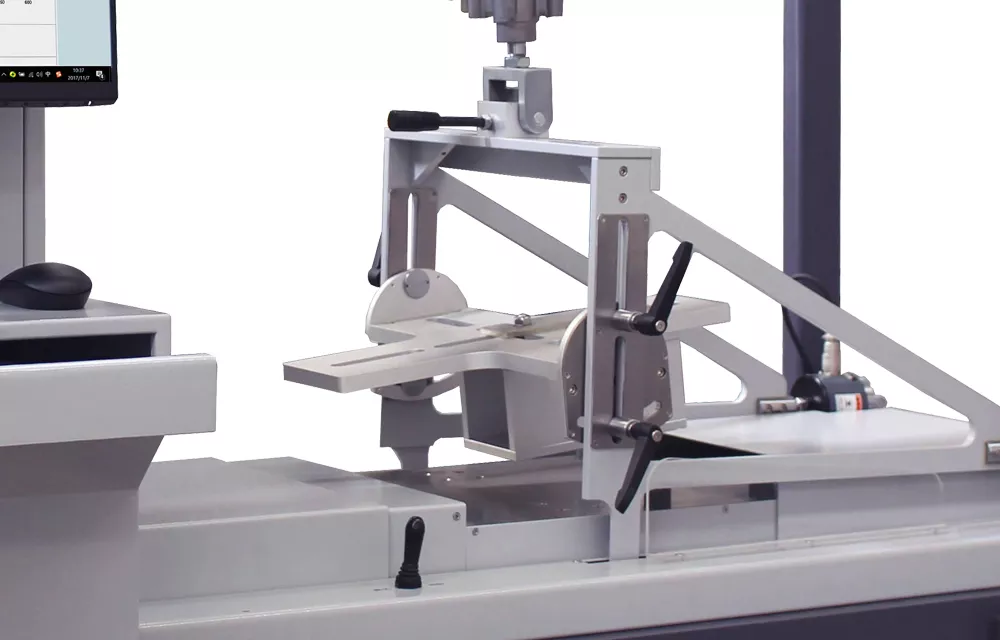

- The GT-7012-BEA is specifically designed to assess the coefficient of friction between shoes and floorings for evaluating the slip resistance of shoes.

- During a COF test, the specimen in contact with a test flooring is subjected to a vertical force and moved horizontally relative to the surface. The friction force is measured for calculating the coefficient of friction.

-

Standards

- ISO 13287-2019

- ISO 20344-2021 5.14

- ISO 20345-2021 5.3.5

- EN ISO 13287-2019

- GB/T 28287-2012

- SATRA TM144-2011

- ASTM F2913-2019

- GB/T3903.6-2017

- BS EN ISO 13287-2019

Principle

The GT-7012-BEA is specifically designed to assess the coefficient of friction between shoes and floorings for evaluating the slip resistance of shoes. During a COF test, the specimen in contact with a lubricated flooring is subjected to a vertical force and moved horizontally relative to the surface. The friction force is measured for calculating the coefficient of friction.

Quality control:

The slip resistance tester plays an significant role in quality control assurance of shoes, ensuring they meet standard requirements and customers' expectations.

Research and development:

Provides valuable insights into shoe slip performance by different materials and structures to assist manufacturers in product research and development.

Product design improvement:

Enables manufacturers to verify the slip performance efficiency of shoe materials by providing accurate test results.

Product competitiveness:

Ensures products maintain superior competitiveness through the slip performance evaluations conducted under various real-world replicated scenarios.

Objective test results:

Utilizes a standardized test procedure to provide objective test results and repeatable assessments, ensuring conformity to shoe slip performance standards.

Efficient testing:

Thanks to its advanced programmability, the slip resistance tester automatically conducts tests based on specified test conditions, enhancing testing efficiency and reducing manual operation.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Authentic simulation

Simulates real-world scenarios under various lubrication, load, and speed conditions to accurately assess shoe slip performance.

Wide applicability

Provides comprehensive capabilities for evaluating a wide range of shoes and shoe materials.

Reliability

Utilizing high-precision servo control system to precisely conduct testing and ensure test results accuracy.

Flexible test options

The dedicated software and flexible parameters settings allow operators to easily set and modify test conditions to meet a variety of testing requirements.

Real-time monitoring

By monitoring and recording real-time data during test processes, the GT-7012-BEA offers clear insights into the shoe slip performance.

Powerful database

Allows operators to record and search test results to assist them in materials performance evaluation.

-

左右滑動看表格

左右滑動看表格Capacity Vertical direction: 1000 N; horizontal direction: 1000 NLoad accuracy Vertical direction: ±0.5%; horizontal direction: ±0.5% Speed range 100 mm/s to 500 mm/s (adjustable) Standard speed 300 mm/s±3 mm/s Vertical force range 300 N to 600 N (adjustable) Standard vertical force ≧Size 250: 500±25N

<Size 250: 400±20NVertical force loading system Proportional valve Wedge shaped angle gauge 7° Controller U70 control system Communication interface RJ45 Software 7012-BEA testing software Power 1∮ AC 220V 50Hz 10.9A 2.4kw (or specify)

*Product design and specifications are subject to change without notice.

-

Details

Standards

- ISO 13287-2019

- ISO 20344-2021 5.14

- ISO 20345-2021 5.3.5

- EN ISO 13287-2019

- GB/T 28287-2012

- SATRA TM144-2011

- ASTM F2913-2019

- GB/T3903.6-2017

- BS EN ISO 13287-2019

Principle

The GT-7012-BEA is specifically designed to assess the coefficient of friction between shoes and floorings for evaluating the slip resistance of shoes. During a COF test, the specimen in contact with a lubricated flooring is subjected to a vertical force and moved horizontally relative to the surface. The friction force is measured for calculating the coefficient of friction.

Quality control:

The slip resistance tester plays an significant role in quality control assurance of shoes, ensuring they meet standard requirements and customers' expectations.

Research and development:

Provides valuable insights into shoe slip performance by different materials and structures to assist manufacturers in product research and development.

Product design improvement:

Enables manufacturers to verify the slip performance efficiency of shoe materials by providing accurate test results.

Product competitiveness:

Ensures products maintain superior competitiveness through the slip performance evaluations conducted under various real-world replicated scenarios.

Objective test results:

Utilizes a standardized test procedure to provide objective test results and repeatable assessments, ensuring conformity to shoe slip performance standards.

Efficient testing:

Thanks to its advanced programmability, the slip resistance tester automatically conducts tests based on specified test conditions, enhancing testing efficiency and reducing manual operation.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Authentic simulation

Simulates real-world scenarios under various lubrication, load, and speed conditions to accurately assess shoe slip performance.

Wide applicability

Provides comprehensive capabilities for evaluating a wide range of shoes and shoe materials.

Reliability

Utilizing high-precision servo control system to precisely conduct testing and ensure test results accuracy.

Flexible test options

The dedicated software and flexible parameters settings allow operators to easily set and modify test conditions to meet a variety of testing requirements.

Real-time monitoring

By monitoring and recording real-time data during test processes, the GT-7012-BEA offers clear insights into the shoe slip performance.

Powerful database

Allows operators to record and search test results to assist them in materials performance evaluation.

-

Specifications

左右滑動看表格

左右滑動看表格Capacity Vertical direction: 1000 N; horizontal direction: 1000 NLoad accuracy Vertical direction: ±0.5%; horizontal direction: ±0.5% Speed range 100 mm/s to 500 mm/s (adjustable) Standard speed 300 mm/s±3 mm/s Vertical force range 300 N to 600 N (adjustable) Standard vertical force ≧Size 250: 500±25N

<Size 250: 400±20NVertical force loading system Proportional valve Wedge shaped angle gauge 7° Controller U70 control system Communication interface RJ45 Software 7012-BEA testing software Power 1∮ AC 220V 50Hz 10.9A 2.4kw (or specify)

*Product design and specifications are subject to change without notice.