- The GT-7012-NGBH is specifically designed to evaluate the resistance of outsoles and molded soles to abrasion.

- The abrasive resistance of outsoles is assessed by measuring the rubbing length after the test piece has been rubbed at a constant speed for a specified time under a prescribed load.

-

Standards

- GB/T 3903.2

Principle

The GT-7012-NGBH is specifically designed to evaluate the resistance of outsoles and molded soles to abrasion. The abrasive resistance of outsoles is assessed by measuring the rubbing length after the test piece at any position has been rubbed at a constant speed for a specified time under a prescribed load.

Comprehensive assessment:

Provides standardized and reliable test methods to thoroughly evaluate the quality of outsoles for abrasion resistance.

Adjustable test conditions:

Offers adjustable test conditions including pressure, speed, and time to meet different scenarios of testing requirements.

Flexible test positions:

Allows for testing at any desired position on the test piece to replicate various conditions in real-world scenarios.

Quality assurance:

Ensuring outsoles products consistently meet specific quality standards during production processes.

Product research and development:

Enables designers to observe how different materials respond to abrasion, allowing for adjustments to be made before mass production to improve durability and safety.

Customer satisfication:

By ensuring the ability to resist abrasion on completed outsoles, the GT-7012-NGBH helps manufacturers in effectively meeting customers' product requirements.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Authentic simulation

Simulates wearing and tearing of outsole during regular use to assess its abrasion resistance.

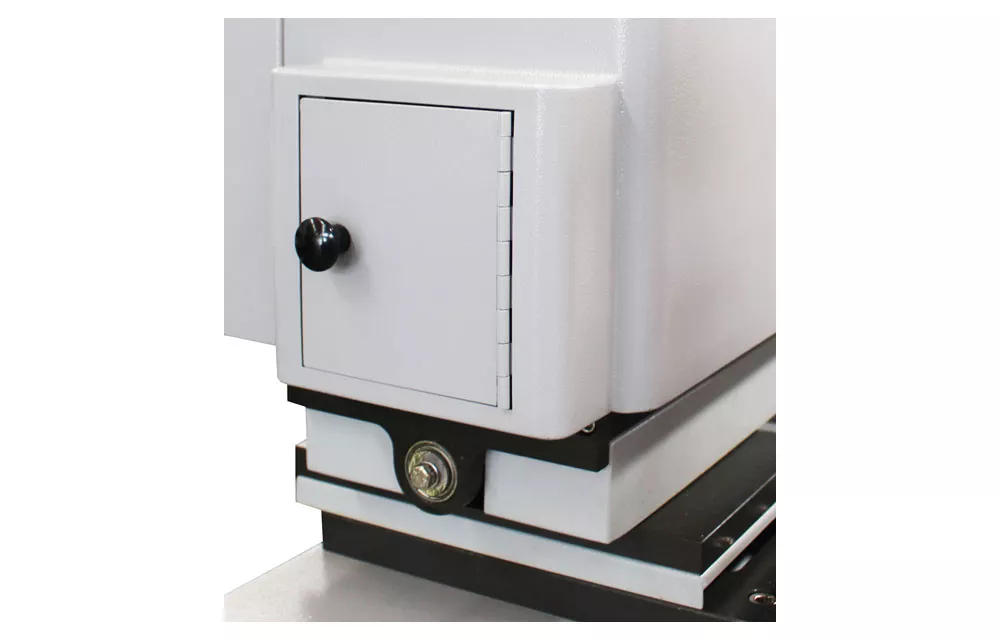

Adjustable mechanism

Compatible with various shapes and sizes of outsoles for testing through the adjustable mechanism

Touchscreen interface

The intuitive and user-friendly interface enables operators to easily set parameters and operate tester.

-

左右滑動看表格

左右滑動看表格Grinding wheel 20±0.1mm diameter and 4±0.1mm thickness Rotating speed 191 ± 5 rpm (optional: 100 to 300 rpm) Load between grinding wheel and sample Adjustable within 19.6N Load 4.9 N (optional: 0 to 19.6N) Test time Continuous 20 min Dimensions (W×D×H) 69 cm ×53 cm ×80 cm (approx.) Power 1∮ AC 220V 50Hz (or specify)

*Product design and specifications are subject to change without notice. -

-

Details

Standards

- GB/T 3903.2

Principle

The GT-7012-NGBH is specifically designed to evaluate the resistance of outsoles and molded soles to abrasion. The abrasive resistance of outsoles is assessed by measuring the rubbing length after the test piece at any position has been rubbed at a constant speed for a specified time under a prescribed load.

Comprehensive assessment:

Provides standardized and reliable test methods to thoroughly evaluate the quality of outsoles for abrasion resistance.

Adjustable test conditions:

Offers adjustable test conditions including pressure, speed, and time to meet different scenarios of testing requirements.

Flexible test positions:

Allows for testing at any desired position on the test piece to replicate various conditions in real-world scenarios.

Quality assurance:

Ensuring outsoles products consistently meet specific quality standards during production processes.

Product research and development:

Enables designers to observe how different materials respond to abrasion, allowing for adjustments to be made before mass production to improve durability and safety.

Customer satisfication:

By ensuring the ability to resist abrasion on completed outsoles, the GT-7012-NGBH helps manufacturers in effectively meeting customers' product requirements.

Standard conformity:

Ensures that products meet industry standards and satisfy quality expectations in the market.

-

Features

Authentic simulation

Simulates wearing and tearing of outsole during regular use to assess its abrasion resistance.

Adjustable mechanism

Compatible with various shapes and sizes of outsoles for testing through the adjustable mechanism

Touchscreen interface

The intuitive and user-friendly interface enables operators to easily set parameters and operate tester.

-

Specifications

左右滑動看表格

左右滑動看表格Grinding wheel 20±0.1mm diameter and 4±0.1mm thickness Rotating speed 191 ± 5 rpm (optional: 100 to 300 rpm) Load between grinding wheel and sample Adjustable within 19.6N Load 4.9 N (optional: 0 to 19.6N) Test time Continuous 20 min Dimensions (W×D×H) 69 cm ×53 cm ×80 cm (approx.) Power 1∮ AC 220V 50Hz (or specify)

*Product design and specifications are subject to change without notice. -

Video